The most read Journal of Applied Polymer Science articles from January include electronic materials, polyolefines, antibacterial composites, and hydrogels. In addition, the journal is introducing an open access option: see our open polymers article for more details.

Polypyrrole/MWCNT-gr-PSSA composite for flexible and highly conductive transparent film

Lim from Hanyang University and co-workers prepare a highly conductive composite with nanotubes in a polymeric matrix, for indium tin oxide-free organic solar cells. After solvent doping the polymer deposited on a polyethylene substrate showed a remarkably high conductivity. The composite has good potential to be deployed in flexible anodes for organic solar cells applications.

Functionalization of polypropylene at high temperature under oxidative/inert environment

Akolekar et al. at Dow Chemical show they can introduce a number of functional groups into polypropylene at high temperature with a yield of up to 20, generating a highly stable functional polymer for a variety of applications.

Preparation and antibacterial activity of polyvinyl alcohol/regenerated silk fibroin composite fibers containing Ag nanoparticles

Through electrospinning and annealing of the resulting fibers, Li and co-workers at Soochow University show they can produce polymer fibers with embedded silver-containing nanoparticles that possess strong antimicrobial properties.

Swelling behavior and structural characteristics of polyvinyl alcohol/montmorillonite nanocomposite hydrogels

Sirousazar and coworkers examine the structure-property relationships in polymer/clay composite hydrogels. The composites are tougher than pure polymer hydrogels, and the swelling can be tailored by the clay content to suit applications especially in the biomedical area.

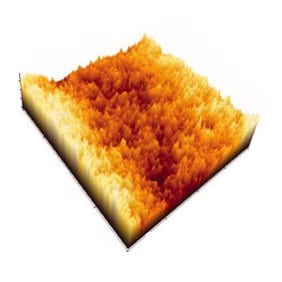

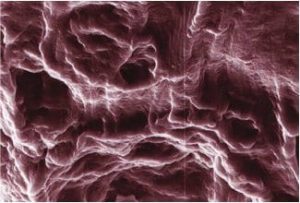

Multiwalled carbon nanotube polymer composites: Synthesis and characterization of thin films

Multiwalled carbon nanotube polymer composites: Synthesis and characterization of thin films

A classic from 2002 from Safadi et al. at the University of Kentucky on ultrasonic dispersion of nanotubes in polymer matrices. A nanotube loading of 2.5% in weight changes the composite from insulating to conductive, and doubles the tensile modulus.