Despite extensive studies on developing self-healing materials, only a few attempts have been made to enable other functionalities such as conductivity. Developing materials with autonomous intrinsic self-healing properties and electrical conductivity is essential for the advancement of emerging fields such as artificial skins, medical devices, soft robotics, and flexible systems. However, designing a material with multiple functionalities still remains a big challenge. A vast majority of the investigation on intrinsic self-healing materials is focused on designing stimuli-responsive self-healing materials, so-called non-autonomous self-healing systems, triggered by light, temperature, electricity, and redox potential stimuli. Most of the designed autonomous conductive self-healing materials fail to adopt in practical applications because of the lack of stretchability, bulk conductivity, pressure sensitivity, or mechanical performance.

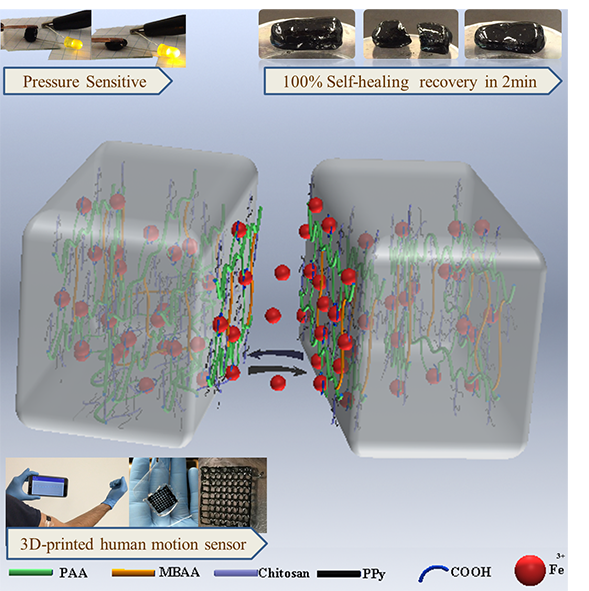

To address these problems, Malcolm Xing and colleagues in University of Manitoba have designed a new method which employs a combination of physical and chemical crosslinking to meet the highest efficiency in self-healing, while maintaining the mechanical stability and conductivity. The hydrogel is prepared through a two-step synthesis. Polypyrrole (PPY) is linked to the double-bond decorated chitosan (DCh) to form PPy-grafted chitosan (DCh-PPy). The acrylic acid (AA) monomers are polymerized in DCh-PPy using iron ions to produce double network hydrogel. The reversible ionic interactions between AA and DCh-PPy, and iron ions contribute to an autonomous self-healing property.

The new polymer enables a complete mechanical recovery only 2 minutes after being cut. Additionally, around 90% of electrical properties is recovered after 30 seconds without any external stimuli. The developed material shows ultra-stretchability, accurate pressure sensitivity as well as high conductivity. Autonomic repeatable self-repairing capability after damage and shear thinning behavior enable this hydrogel to be used as 3D printing materials. The results of the study are published in Advanced Materials.