Owing to unprecedented alloy design rules, high entropy alloys (HEAs) have drawn great attention over the past decade.

The concept of non-equiatomic HEAs, first put forward by Prof. Raabe and his colleagues, has greatly expanded the compositional space of HEA design. Outstanding mechanical properties have been achieved in HEAs through various strengthening and deformation mechanisms. However, the application field of HEAs is quite limited, with HEAs being pursued primarily as replacements for conventional structural materials. It is important to expand the application domain of HEAs, for example into highly functional materials and for applications in extreme environments to make this research field achieve full of vitality and impactfully translate into the commercial sector.

From superelasticity to ultrahigh strength, martensitic phases with different substructures enable materials to exhibit a variety of properties. In general, one specific martensite type, lath, plate, etc., corresponds to one specific material. It is a challenge to design a given material, namely a single composition, to produce multiple forms of martensite types.

In a synergistic effort to combine HEA design with martensite design, Professor Kenneth Vecchio and his research group from the NanoEngineering Department at the University of California-San Diego successfully fabricated multifunctional non-equiatomic high entropy alloys with superelastic, high damping, and excellent cryogenic properties, within a single composition.

This new class of aged non-equiatomic FeNiCoAlTaB (NCATB) HEA exhibits tunable properties from cryogenic/ambient superelasticity to ultra-high strength through controlling the nature or type of martensite that forms.

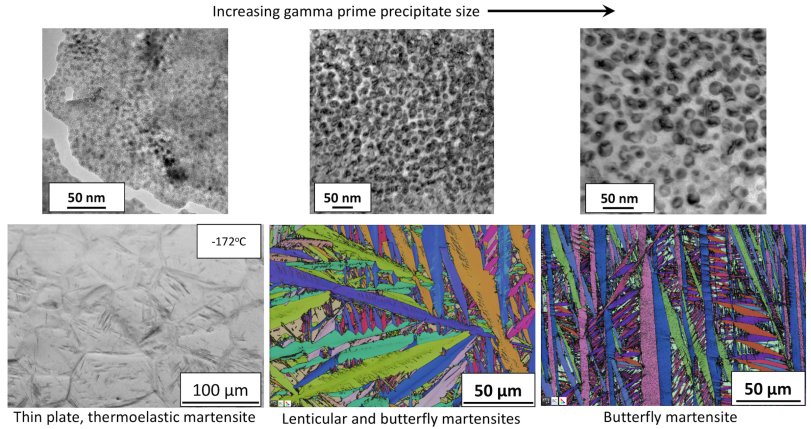

Depending on the size of γ’-Ni3Al (L12) precipitates, which can be formed in the alloy, thin-plate, lenticular, butterfly and lath-like martensites can form in NCATB-HEA. When thin-plate thermoelastic martensite is favored, a superelastic strain of about 0.025 (ambient) and ≈0.01 (cryogenic) can be achieved with a high yield stress of ≈800 MPa and a high-damping effect (10 times higher than Cu-Al-Ni superelastic alloy).

While for butterfly and lath-like martensite dominated NCATB-HEA, an ultra-high yield stress over 1.1 GPa can be achieved, with no superelastic behavior. Professor Vecchio said, “This alloy system can help to expand the application domain of HEAs, for example into high-damping applications, robust actuators, space exploration and other structural material applications, exploiting more functional properties.”