Airborne particulate matter (PM) pollution, especially PM2.5 (aerodynamic diameter ≤ 2.5 μm), has a growing impact on public health, production efficiency, and even forms part of the underlying problems with the deteriorated climate and ecosystems. Currently, fibrous filters are widely used for PM filtration, because of their integrated features, such as cost-effectiveness, energy-efficiency, changeable filter design, and application universality. However, the filtration capacity of existing fibrous filters is still restricted by their thick diameter, low porosity, and limited frontal area. Therefore, the ability to solve this problem would have broad technological implications for various air filtration applications ranging from individual protection, and industrial security to environmental governance.

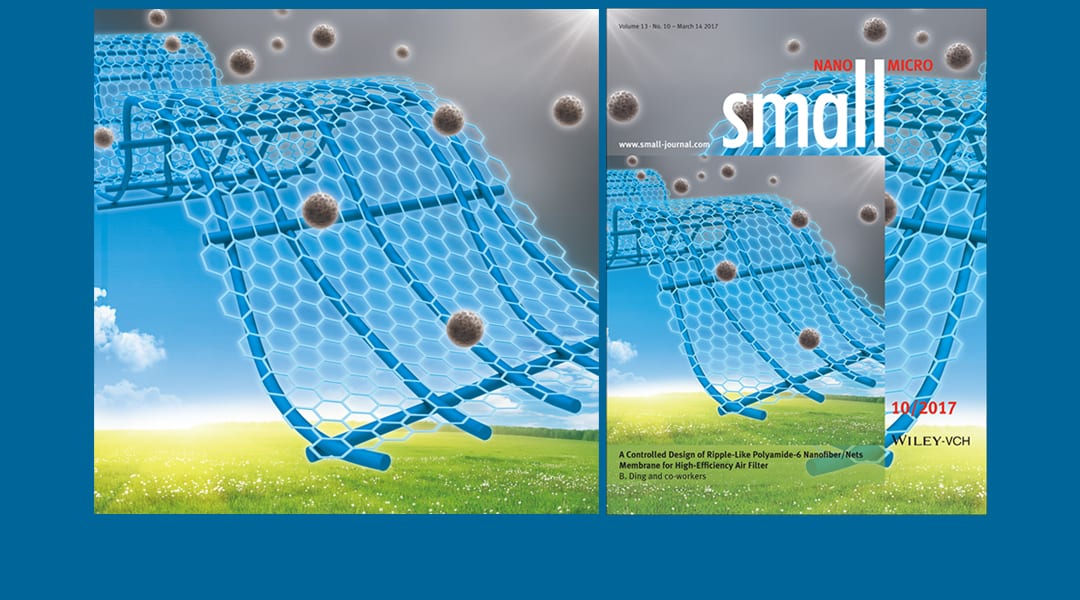

Prof. Bin Ding and co-workers from Donghua University, China, have now proposed a facile and scalable strategy to fabricate a ripple-like polyamide-6 nanofiber/nets (PA-6 NF/N) membrane filter for effective air filtration via a combined electrospinning/netting technique with a receiving substrate design. By facilely adjusting the pleat span and pleat pitch of a polyethylene terephthalate (PET) filament framework, their approach allows PET filaments to be orderly embed into two-dimensional PA-6 nanonet layers with Steiner-tree structures with a nanoscale diameter of ≈20 nm.

The resultant ripple-like membrane is endowed with extremely small pore size, a highly porous structure, and hugely extended frontal surface. These integrated structural advantages enable the ripple-like PA-6 NF/N filter to filtrate ultrafine airborne particles (300–500 nm) with high removal efficiency of 99.996%, low air resistance of 95 Pa, and robust quality factor of >0.11 Pa–1. Furthermore, the filter is superlight weight at only ≈0.9 g m–2, and can capture airborne particles in a physical sieving manner, revealing the capacity of removing the negative impacts of high airflow speed, electret failure, and high humidity.

This novel approach has the potential to give rise to the novel generation of filter media displaying enhanced filtration capacity for various applications thanks to the nanoscale features and designed macrostructures. In applications such as high-performance respirators for individual protection, filter canisters, filter grids that can be used in engine intake, appliances, medical equipment, and cleanrooms.