The past ten years have seen the development of a novel family of antireflective surfaces, based on the presence on the top of the reflective material of a nano-textured layer which causes a gradual variation of the refractive index at the interface with air, according to the so called “moth eye” effect. This effect has been already exploited on silicon in order to improve efficiency of solar cells. Recent efforts are addressed to reduce by this approach reflectance of transparent plastics, more and more utilized in construction, optics, automotive. For this class of materials the process of surface nano-texturation must be cold (below the glass transition temperature) and capable of saving their transparency.

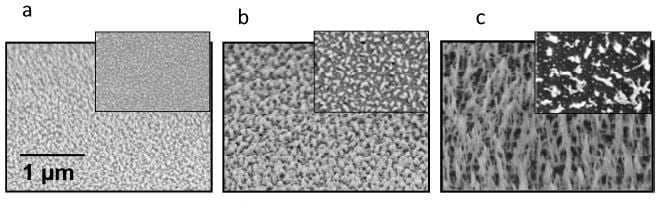

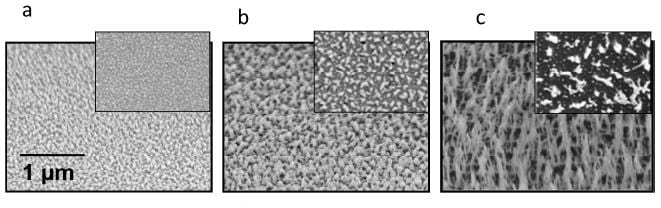

New, in new work, nano-texturation of plastics, so far developed for modifying their wetting properties, is performed with a single-step mask-less plasma etching method which allows for fine size control (from 50 to 1000 nm) of random, but homogeneously distributed, nanostructures. Experiments focused on polycarbonate show that the shape can be controlled using different feed gases: in particular by passing from CF4 to O2 feed gas a transition from bump-like to wire-like is observed. Wire-like structures are significantly more efficient in attenuation of reflectance of visible and near-infrared light and avoid, due to their thinner apexes and narrower distribution, visible light scattering, thus saving material transparency. The same type of nanostructures, as previously demonstrated, can impart to the considered material also an extreme wetting behavior, either super-hydrophobic or super-hydrophilic.