A team in Japan have made stronger than ever metal-carbon nanotubes junctions by nanowelding multiwalled carbon nanotubes to the contact surface.

Carbon nanotubes (CNTs) have been the next big thing in materials science for some time now, and researchers are looking for the best way to take advantage of their unique and superior properties. Many CNT-based devices have been fabricated, with variable results. In general criteria for these are that the CNT-metal contact should be mechanically robust, reliable, and conduct electricity. A common problem in current devices is that the CNT-metal contact fails, so researchers are looking for ways to improve and strengthen this contact.

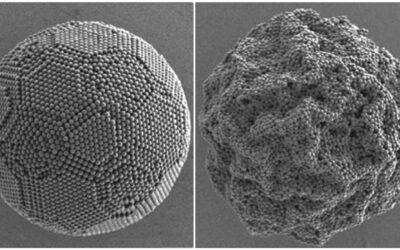

Dr Ming-Sheng Wang and colleagues at the National Institute for Materials Science in Tsukuba, Japan may have solved the contact failure problem by making extremely strong CNT-tungsten carbide-tungsten metal contacts. They used multiwalled carbon nanotubes (MWCNTs) and effectively soldered all of the shells of the MWCNTs to the carbide surface using a modified transmission electron microscope to perform “nanowelding”.

The resulting junctions are extremely strong; at around 5-15 GPa they are even stronger than some of the measured strengths for MWCNTs themselves as well as being three times stronger than recently measured values for Co-CNT junctions. Not only this, but electron field emission tests on the resultant devices prove that their MWCNT junctions fail at much higher voltages than do conventional CNT devices.

The team have studied the failure modes of their MWCNT junctions and noted that failure in their system is usually of the MWCNT itself rather than of the contacts, as is normal in field emission devices. They believe that their super-strong junctions could have applications in nanoresonators and mechanical sensors as well as in electron field-emitters, because of their low contact resistance and high mechanical strength.