Subsequent to a distortion in shape, shape memory materials have the ability to return to their initial form when an external stimulus, e.g. heat, is applied. The behaviour, known as the shape memory effect, is normally looked at on a macroscopic scale, i.e. visual shape changes. By investigating the viscoelastic behaviour and mechanical properties of a polyurethane, Tcharkhtchi et al. now show the existence of a properties memory effect that does not exactly reflect that of the shape memory.

Subsequent to a distortion in shape, shape memory materials have the ability to return to their initial form when an external stimulus, e.g. heat, is applied. The behaviour, known as the shape memory effect, is normally looked at on a macroscopic scale, i.e. visual shape changes. By investigating the viscoelastic behaviour and mechanical properties of a polyurethane, Tcharkhtchi et al. now show the existence of a properties memory effect that does not exactly reflect that of the shape memory.

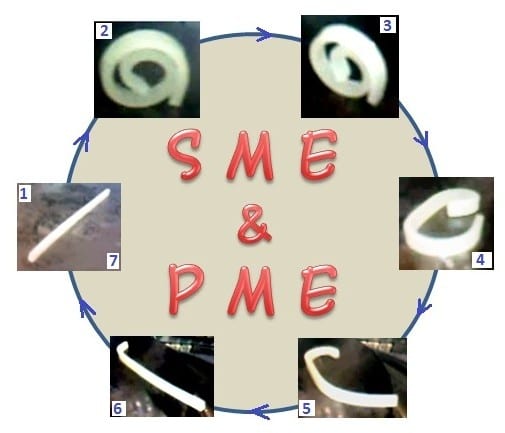

Polyurethane is a shape memory polymer that is known to be capable of 100% shape regain: if it is stretched above its glass transition temperature then cooled to fix the new shape, reheating it to above the start of the glass transition zone facilitates complete recovery of its original form. Tcharkhtchi and colleagues deformed the polyurethane at temperatures in the glass transition zone or higher. They performed tensile tests, recovery tests, and stress-strain experiments, and studied the viscoelastic behaviour using dynamic mechanical thermal analysis, the Cole-Cole method and a biparabolic model. As reported in the Journal of Applied Polymer Science, the authors found that the polymer does not retain its initial properties even when it completely regains its shape, for example, the storage modulus curve varies and the Young’s modulus decreases.

The authors attribute the behaviour to a change in the microstructure that modifies the free volume fraction to an extent that is not recovered when the polymer regains its shape. The work probes deeper into the materials memory effect and develops our understanding of the phenomenon.