They can absorb vast amounts of oil or organic compounds, yet they are nearly as light as air: highly porous solids made of a three-dimensional network of carbon nanotubes. Chinese scientists have now introduced a simple technique for the production of these ultralight, flexible, fire-resistant aerogels. Their method begins with bacterial cellulose as an inexpensive starting material. Their fibrous lightweights can “suck” organic contaminants from polluted water and could possibly be used as pressure sensors.

Their unique properties—low density, highy porosity, high specific surface, and high electrical conductivity—make carbon aerogels promising new materials. They could be used as catalyst supports, electrodes for supercapacitors, adsorbents, and gas sensors, as well as for synthetic muscles. However, there is still no simple, industrially and environmentally friendly method for the production of these attractive lightweights.

A team led by Shu-Hong Yu at the Hefei National Laboratory for Physical Sciences at Micrscale (HFNL), Univeristy of Science and Technology of China is pursuing their production from biomass. They selected bacterial cellulose, a commonly used, inexepensive, nontoxic form of biomass consisting of a tangled network of cellulose nanofibers. This material can easily be produced on an industrial scale through microbial fermentation.

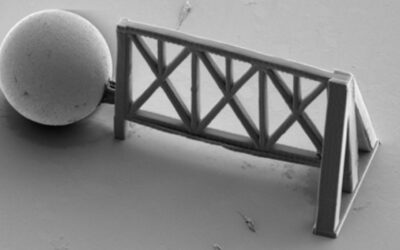

The researchers trimmed off small pieces of the tangled cellulose nanofibers. These were freeze-dried and then pyrolyzed at 1300 °C under argon. This converts the cellulose into graphitic carbon. The density decreases but the network structure remains intact. The result is a black, ultralight, mechanically stable aerogel. Because it is porous and highly hydrophobic, it can adsorb organic solvents and oils—up to 106 to 312 times its own weight. It draws oil out of an oil/water mixture with high efficiency and selectivity, leaving behind pure water. This makes the new aerogel an ideal candidate for cleaning up oil spills or sucking up nonpolar industrial pollutants. The absorbed substances can easily be removed from the gel through distillation or combustion, allowing the gel to be used again.

The extraordinary heat- and fire-resistence of this material are particularaly noteworthy: repeated treatment with the flame of a torch caused no changes in its form or inner three-dimensional pore structure.

The high electrical conductivity of the aerogel also suggests the possibility of electronic applications. The material has high mechanical flexibility. It can be compressed to about 10 % of its original volume and will subsequently expand back to nearly its original shape. Its conductivity decreases in a nearly linear fashion with increasing compression, which could allow the aerogel to be used as a pressure sensor.

Source: Angewandte Chemie