Getzner has developed a new range of elastic polyurethane (PU) materials, which prevent the negative effects of impact loads. “Installing our new materials improves both working conditions and occupational safety, as people are protected from impacts and vibrations. In machines and electronic equipment, it ensures uninterrupted operation and less material wear,” pledges Marcel Mattheus, product manager at Getzner.

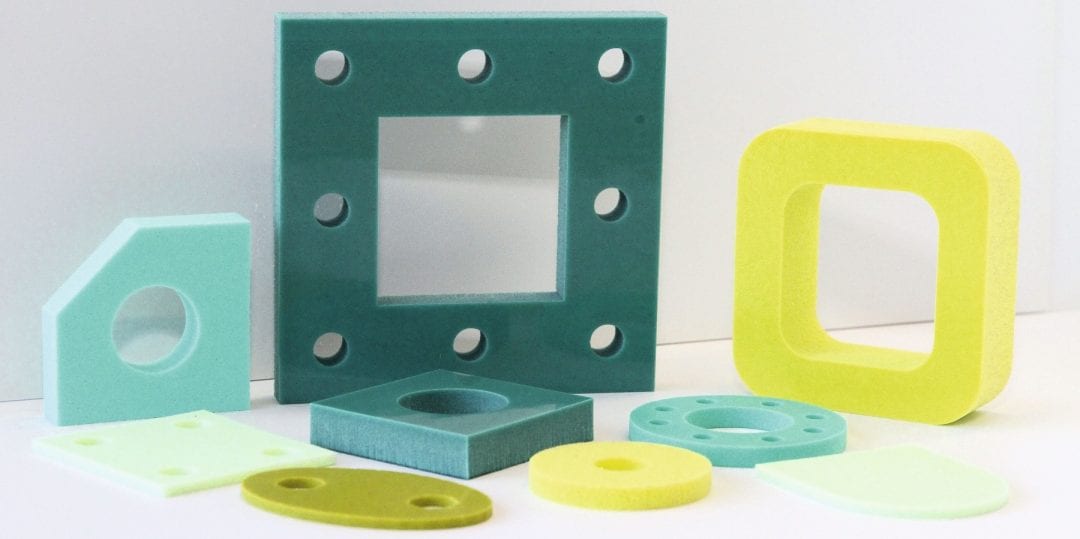

Six types of Sylodamp in various colors and finely graded levels of stiffness absorb impacts in different load ranges. Getzner offers customized solutions as well as punched parts and cuttings in a wide variety of dimensions. “In order to achieve maximum effectiveness, we individually calculate the optimal material design to satisfy any requirement based on FEM. Using the correct, tailored materials is the key to highly effective damping. The experience and personal touch of our experts really makes the difference here,” explains Markus Heim, Sylodamp project manager at Getzner.

Getzner has developed new elastic materials that have already proven themselves in a wide range of applications e.g. machine mountings. Source: Getzner

Elastic mounting prevents excessive wear of mechanical components from quick material fatigue, even when continuous impact loads are involved. The material has already proven itself in numerous applications in a wide range of fields, including as impact protection in mechanical and apparatus engineering; as vibration protection under machine mountings, compressors, baggage carousels and conveyor belts; as a damping element in vehicle construction; to improve precision in sensitive equipment like displays and microscopes; to absorb vibrations in sports hall floors; as transport protection for heavy goods; to protect the musculoskeletal system from abrasion or overloading in sports fabrics or as shoe insoles.

The damping characteristics of the PU cancel out shock pulses much more quickly; a potential rebound is prevented thanks to the material’s impact resilience. The material absorbs specific energy extremely effectively over the long term and with no change in quality thanks to its mixed-cellular pore structure, as told by the company. The damping material is UV and ozone resistant, and is produced without generating any greenhouse gases.