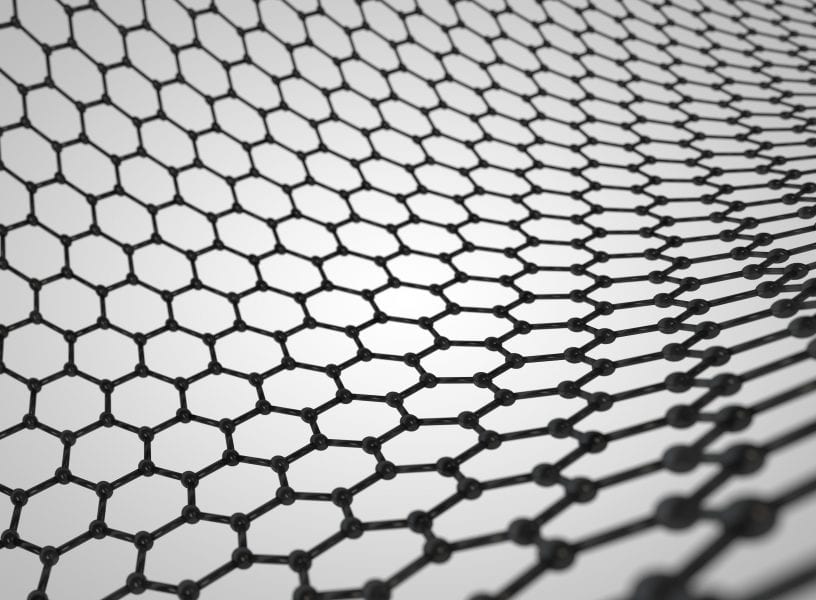

In solid materials, heat is carried by acoustic phonons and electrons. The thermal conductivity (K) of metals is mainly attributed to high concentration of transport electrons. In this context, silver has the maximum thermal conductivity with a K value around 429 W m-1 K-1 at room temperature. To reach higher thermal conductivity, the only option is to use non-metallic materials, as their heat conduction is usually dominated by phonons, the particle-core vibrations in a crystal lattice, as in the cases of diamond and semi-metallic graphite. For the same material, K is mainly scaled with the size of crystal domain but limited by the concentration of defects, such as interfaces, boundaries, impurities, and holes. Therefore, a prominent thermal conductive material is usually pure, highly crystallized and defect-free, which in turn inevitably leads to brittleness because of the strong bonding and close-packed three-dimensional structure. Hence, prominent K and exceptional flexibility are hard to be integrated into one macroscopic material.

In a recent paper published in Advanced Materials, Prof. Chao Gao and colleagues in Zhejiang University report an ultra-high thermal conductive yet super-flexible graphene film. They fold the atomic thin crystals of neat large-sized graphene into micro-folds. Using a debris-free giant graphene oxide to reduce defective grain boundaries and extremely high-temperature annealing process to obtain defect-free graphene sheets results in a super high K of 1940 ± 113 W m−1 K−1, which is around five times more than copper’s thermal conductivity. On the other hand, they press semi-fullerene-like micro-gasbags into micro-folds to accommodate large elongation (16%) under external tension and provide enough deformation freedom, for more than 100,000 cycles of bending and 6,000 cycles of ultimate folding.

This design concept and experimental technique strategy can be extended to other two-dimensional nanomaterials such as BN, MoS2, graphdiyne, and black phosphorus, without fundamental obstacles. Various large-area multifunctional two-dimensional materials can be integrated into flexible devices in the real world, spanning from the aerospace industry to smartphones.

Text kindly contributed by authors. Image credit: Artbox/Shutterstock