As a pure metal and as an alloy, titanium is used for many demanding applications, such as in aerospace or in implants in the human body, offering many attractive properties such as a good strength to weight ratio and resistance to corrosion. Nevertheless, further development of materials is always possible, and aside from developing new alloys with new compositions, it is also possible to engineer materials by changing their structure. The process of choosing a material for a particular application used to be mainly governed by the mechanical and physical properties of the material itself, but with the emergence of porous materials new design concepts gave materials designers higher flexibility to meet different requirements for various applications.

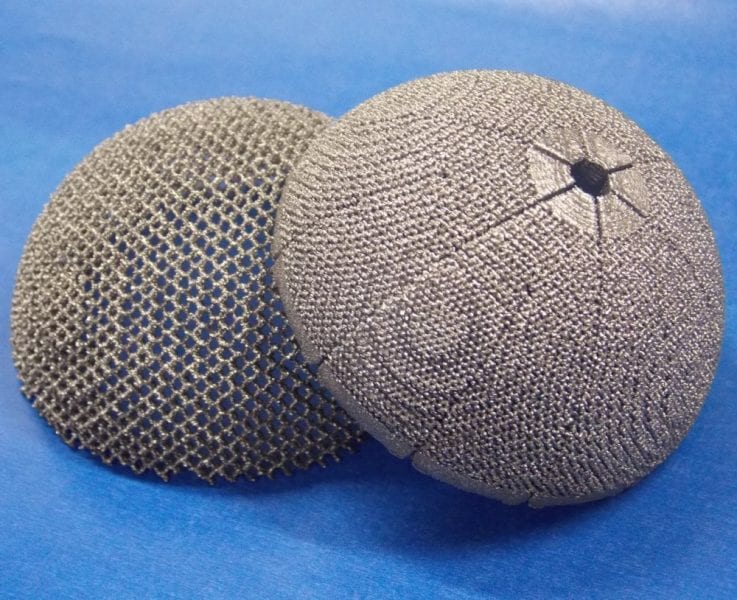

Although porosity is often undesirable in metals, and is seen as a defect, when added in controlled amounts, and in the form of discrete “cells”, the material becomes a foam or a sponge, much lighter in weight with unusual and useful properties and great potential for structural and functional applications, especially where the pores interconnect (an “open-celled” structure). Much research has looked at making porous titanium, for a range of applications.

This Review in Advanced Engineering Materials summarizes the current state of the research area with detailed descriptions of the different manufacturing methods, comparison between foam properties, and the applications they are likely to be used in. The manufacturing techniques are mostly based on powder metallurgical methods, with a number of innovative processing techniques used, and special attention is given to porous titanium processed using additive manufacturing (“3D printing”) methods. The reported properties of such materials are seen to be very varied, with high dependence of behavior such as strength on both the porous structure and also the processing method used. Certain examples of porous titanium have been investigated for use, and here applications in biomedical implants for use in surgery on the human body, electrodes, filters and lightweight sandwich panels are reviewed. The main future challenges for these materials will be how to make larger components, and to take advantage of the wealth of knowledge on processing dense titanium, gleaned from its other applications. This, along with a better understanding of the materials and how they can operate as parts within more complex components, will see their practical uses increasing.