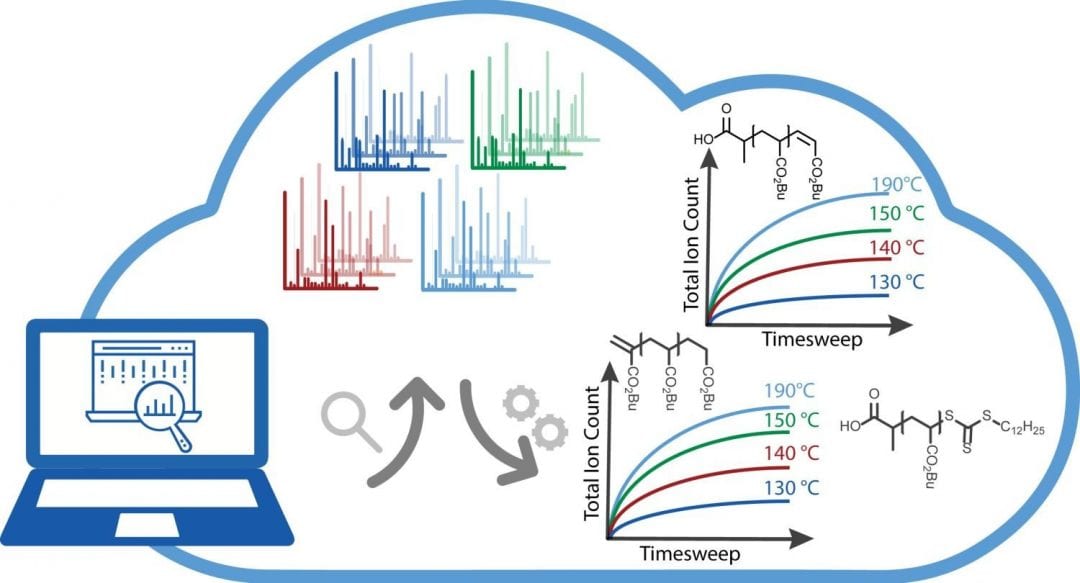

Monitoring and control of polymerization reactions is indispensable to achieve high process safety, high product quality, and competitive production costs. However, despite the enormous progress in sensor technologies, it is still common practice in industry to follow a fixed recipe in time; e.g., follow fixed temperature or feed profiles, with a possible quality control release procedure at the end of the production.

Monitoring and control of polymerization reactions is indispensable to achieve high process safety, high product quality, and competitive production costs. However, despite the enormous progress in sensor technologies, it is still common practice in industry to follow a fixed recipe in time; e.g., follow fixed temperature or feed profiles, with a possible quality control release procedure at the end of the production.

This traditional procedure entirely neglects the progress in sensor technologies and misses the opportunities for use of sensor signals for online optimization. Online optimization in the current context moves from classical time-based recipes to a state-based approach, where the response to the sensor signal determines the process trajectory in order to achieve certain targets.

Therefore, the present special issue of Macromolecular Reaction Engineering, guest-edited by Klaus-Dieter Hungenberg (University of Paderborn) and Wayne F. Reed (Tulane University, New Orleans), presents some of the state-of-the art advances using sensors and modeling for process control and optimization.

Read here for free the Essay by Klaus-Dieter Hungenberg and Wayne F. Reed:

“Online Monitoring, Control, and Optimization of Polymer Reactions and Processes”

and, for a limited time, also the Review by Brenda Colegrove et al.:

“Use of Online Spectroscopy to Control Polymerization in Industrial Processes“