The aircraft performance figures given by both Boeing and Airbus for their novel composite and traditional metallic aircraft demonstrate limitations in structural weight saving potential of composites over metals. To increase the structural efficiency of composite aircraft requires further optimization of these aeronautical structures to maximally exploit the material performance.

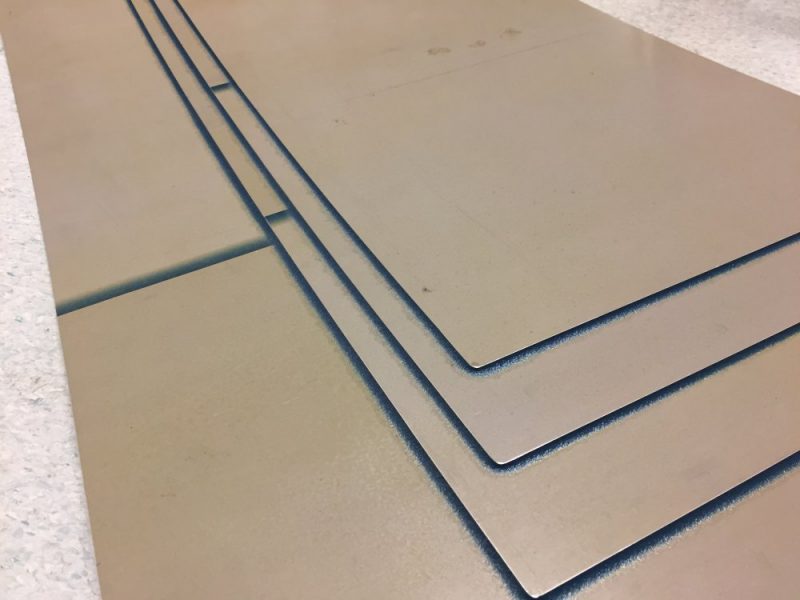

Composites can be optimized by considering the addition of metallic layers to the fibre reinforced polymer layers, similar to the concept of Fibre Metal Laminates. This hybrid structural material technology has been studied extensively in the past decades providing a lot of fundamental knowledge. The challenge of this knowledge, however, is that it is formulated in a certain direction: if one knows the lay-up of the laminate and the loading conditions, then the performance (like strength or durability) can be predicted. For optimization, one needs this knowledge to be formulated in the opposite direction: if one knows the load case and prescribes the required performance, then a lay-up can be predicted.

This requires reversing the developed fundamental theories, which for many of these theories is not straightforward or even possible. This paper demonstrates a way around this problem, by proposing to approximate the knowledge with simple equations. Hence the relation between input (lay-up and load case) and result (performance) is approximated with simple equations. In the optimization of these hybrid structures, these equations can be used to quickly calculate performance, verify whether they meet requirements, and then rank all valid design solutions in the order of most efficient to least efficient. Where with the original theories this procedure takes hours, the adoption of simple approximate equations yields results in seconds.

The paper explains that the approximation implies that accuracy is slightly less than the original theories, but this can easily be accounted for in the design optimization procedure. Attention should be paid to the settings used in the optimization, because depending on the initial settings that one starts with, certain optimal solutions may not be found. This could be solved by either changing the settings, or by limiting the design space, i.e. the amount of solutions identified as potentially possible. Nonetheless, any design solution generated as optimal in this procedure requires the practical design experience with this hybrid material technology in order to confirm further improvement is not possible.