Soft electronics are used in a variety of products, such as wearable electronics, sensory skins, soft robotics and energy systems. Light-emitting elements can add value to soft electronics, by functioning as information displays, providing lighting effects, communicating responses optically or adding increased functionality to implantable medical devices (e.g., emitting light in response to sensor input to release drugs).

One of the simplest light sources that can be incorporated into soft electronics is an alternating current (AC) electroluminescent light. These sources are flexible, emit light uniformly and are inexpensive. However, a new device architecture that utilizes 3D printing onto any substrate would make the systems simpler to construct.

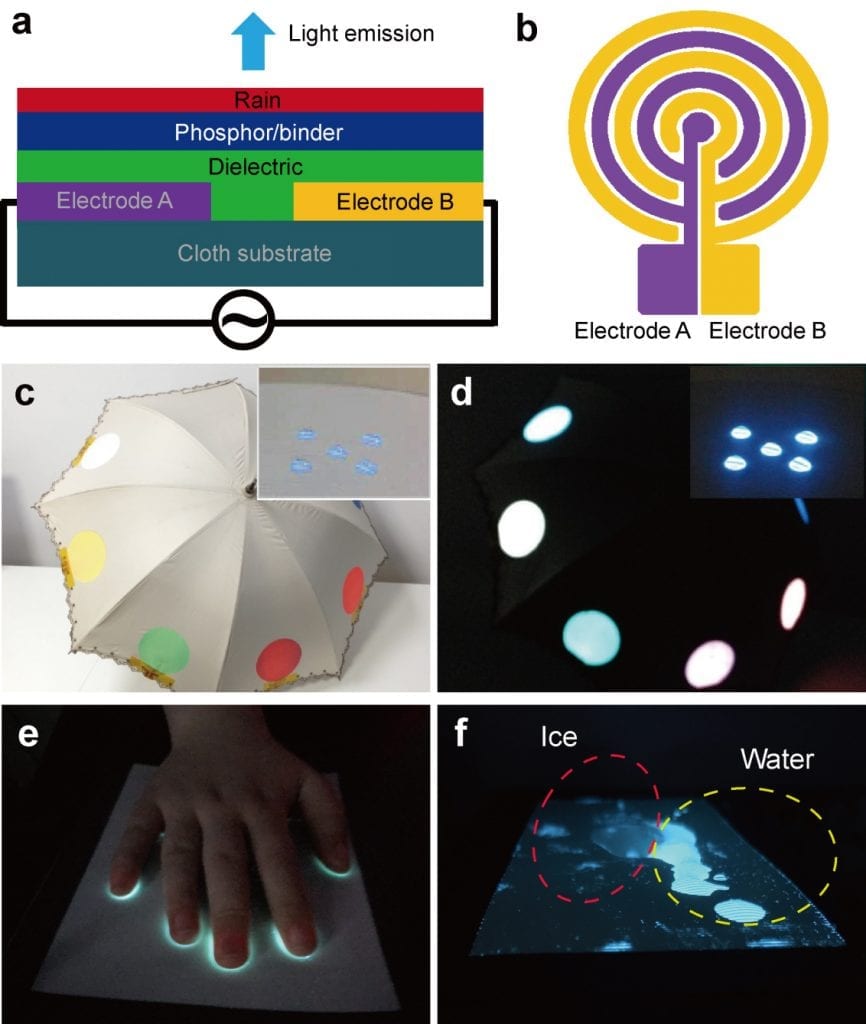

Schematic representations of a,b) the structure of a PEB-ELS-based rain sensor. c) Photograph of an umbrella containing seven circular rain sensors. d) Photograph in the dark of the umbrella of (c) when fully wet. The insets are a magnified view of light emission from five water droplets in (c,d) on the area of one sensor. e) Light emission resulting from the use of a human hand as a polar electrode bridge. f) Photograph showing the decreased luminance from water electrode bridges when the water freezes. More here.

Recently, Dr. Xiuru Xu and co-workers presented their novel, AC-powered, polar-electrode-bridged electroluminescent displays (PEB-ELSs) in Advanced Materials. The displays utilize a dipolar liquid or solid, and a polar material as an electrode bridge. They comprise four components: a pair of electrodes that are optionally parallel and coplanar, light-emitting and dielectric layers, and a modulating electrode layer made of a selected polar material or an electronically conducting film. The opposite electrodes for power input are in different layer stacks, as opposed to the same device stack seen in conventional light-emitting devices.

The diversity of the system is demonstrated, firstly, with an umbrella that automatically lights up when it rains. Secondly, a display that emits light from regions painted with a mixture of oil and water, and lastly, a sensor that lights up differently depending on the presence of water or ice.

Advantages of the concept are that it is simple, easily deployed, scalable and can be inexpensively fabricated by screen printing. It can also utilize various light emitters, and provide a host of sensing functions that result in light emission.

Watch the video abstract of this research, or read the video script here.