Plastics are replacing glass in many products commonly used in our everyday lives. They are easily moulded and can prove superior to glass in a number of ways, including their lower weight and increased toughness. One important aspect in using plastic in certain applications is that they need to be protected by a coating to ensure longevity of the product. Protective coatings, or ‘hardcoatings’ on plastics, are often essential, to provide a barrier that resists abrasion and chemical degradation, significantly increasing plastics durability.

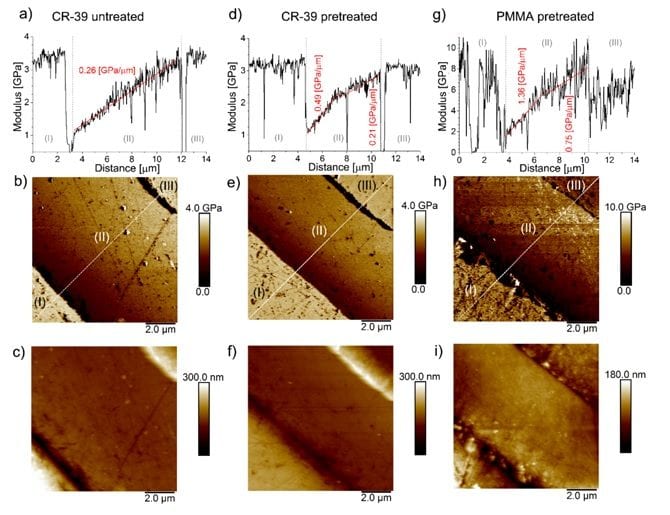

Peak Force AFM images of a cross section of PECVD coating on untreated CR-39 (a–c), pretreated CR-39 (d–f) and pretreated PMMA (g–i) substrates. Images b, e and h display the modulus map of respective samples with I being the substrate, II the coating and III the epoxy resin used to embed the sample for sectioning. Images a, d and g display cross section along the lines marked in the modulus map with linear fits. Images c, f and i display topography maps

These protective coatings can be deposited in number of different ways including: chemical vapour deposition (CVD), plasma-enhanced chemical vapour deposition (PECVD) and sputtering. A new study focused on deposition via PECVD of amorphous SiOxCyHz (a:SiOxCyHz) coatings, which can also be referred to as siloxane coatings, has recently been published. Vacuum deposited “glass-like” coatings (siloxane coatings) could provide protective transparent coatings for plastics. The coatings are aimed at providing mechanical and environmental barriers, at similar thicknesses (~5 to 10 µm) with shorter cycle times than conventional liquid applied and thermally cured coatings. However, to achieve this goal, our understanding of the coating’s deposition and performance needs to be improved.

In this new study, Australian and British researchers expand upon previous adhesion studies to show that the pretreatment process not only affects the adhesion of the coating to the substrate but as a direct result of this, the properties of the coating are also altered. It is critical to establish what is responsible for these changes, whether it be a chemical change as a result of the alteration of the coatings or a structural effect brought about by a change in growth or seeding of the polymer or some combination of both chemical and structural differences. Understanding the influence, the pretreatment on the coating may lead to strategies for improving overall coating performance, as it has been reported that optimum performance has not been obtained for these systems.

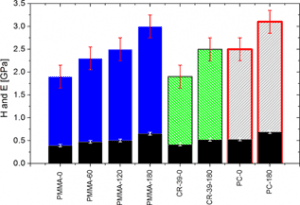

Bar graph showing the hardness at 10% coating depth (bottom bar) and composite modulus (top bar) of coatings deposited on pretreated and untreated CR-39, PC and PMMA

Siloxane coatings, in particular those deposited by plasma processes, find use as mechanical and environmental barriers for plastic substrates. This study highlights that a propanol-based plasma pretreatment drastically improves the adhesion of the coating to transparent plastics. But the greater adhesion of the siloxane to plastic is not the only benefit: more importantly the pretreatment chemically seeded the surface and influenced the growth of the subsequent coating.

Nanomechanical analyses shows the propanol plasma pretreatment process increases the hardness and modulus of the coatings, suggesting an increase in the level of polymer crossing-linking. Pretreatment decreases the RI of the coatings, an indication of increased coating porosity. This is due to an increase in the presence of hydroxyl groups, confirmed by ATR-FTIR, within the coating. The understanding gained will help improve the coatings performance in durability tests, with the aim of matching the conventional liquid applied coatings.