When it comes to nanoscale devices, precision is important. By extension, anything that gives researchers more accurate measurements of the nanoscale materials that make up those devices is also important. That’s why it’s news when someone comes up with a new technique to fine-tune a way of determining Young’s modulus for nanowires.

What is Young’s modulus? Basically, it’s a measurement of how stiff an elastic material is. Fundamentally, it is a measure of how difficult it is to stretch two neighboring atoms. With decreasing size, the surface to volume ratio increases; the atomic arrangement on the surface is different from that in the bulk. So the Young’s modulus of a visible wire is very different from the Young’s modulus of a nanowire – even if they are made of the exact same material.

What is Young’s modulus? Basically, it’s a measurement of how stiff an elastic material is. Fundamentally, it is a measure of how difficult it is to stretch two neighboring atoms. With decreasing size, the surface to volume ratio increases; the atomic arrangement on the surface is different from that in the bulk. So the Young’s modulus of a visible wire is very different from the Young’s modulus of a nanowire – even if they are made of the exact same material.

[If you already know what Young’s modulus is, skip ahead to the next paragraph. For everyone else: Let’s say you take a material and stretch it. If you divide the force exerted to stretch the material into the area of the cross section, you get the “stress.” If you divide the elongation of the material into its original length, you get the “strain.” Elongation is the difference between the original length and the stretched length. (E.g., if the material was 10 centimeters [cm] long, and you stretched it to 12 cm, the elongation would be 2 cm.) If you divide the stress into the strain, you get Young’s modulus. Voila!]

Young’s modulus is an important factor when developing nanoscale mechanical devices, because it tells you how a material will deform when a mechanical load is applied. And if you’re building stuff, you want to know how the building materials will behave, right?

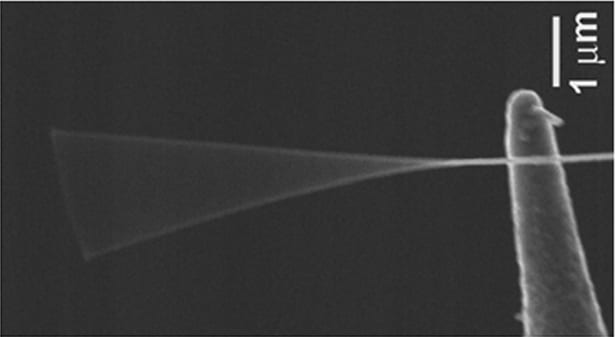

One common method for determining Young’s modulus for nanowires involves fixing a nanowire in place and then vibrating it until it resonates. The resonance frequency can be used to calculate Young’s modulus.

But there’s a problem. A research team at NC State, led by Yong Zhu and Paul Ro, found that the way a nanowire is fixed in place can affect its resonance frequency and – by extension – skew the data that researchers use to calculate Young’s modulus.

To address the problem, Zhu and Ro’s team did a systematic study to find an optimal way to fix the nanowire – and make Young’s modulus measurements more accurate.

The new technique uses a foreign material to clamp the end of the nanowire when it is vibrated. Researchers then measure the resonance frequency. Next, they increase the size of the clamp and repeat the process. Because the wire’s support becomes more rigid as the clamp gets larger, the resonant frequency goes up. This process is repeated with larger and larger clamps until the resonance frequency reaches a constant value from test to test. Once the size of the clamp has stopped being a factor, you’ve found the most accurate measurement.

A paper describing the work, “Measuring True Young’s Modulus of a Cantilevered Nanowire: Effect of Clamping on Resonance Frequency,” is published online in Small. The paper was co-authored by Qingquan Qin, Feng Xu and Yongqing Cao, Ph.D. students at NC State. The research was funded by the National Science Foundation.