Ultrafine fibers offer numerous advanced technology applications. For example, filters made of micro- to nano- fibers can trap microbes and can be used in hospital ventilation systems. Nanofibers can also be deployed to mimic the human cell environment and have been used widely in tissue regeneration strategies.

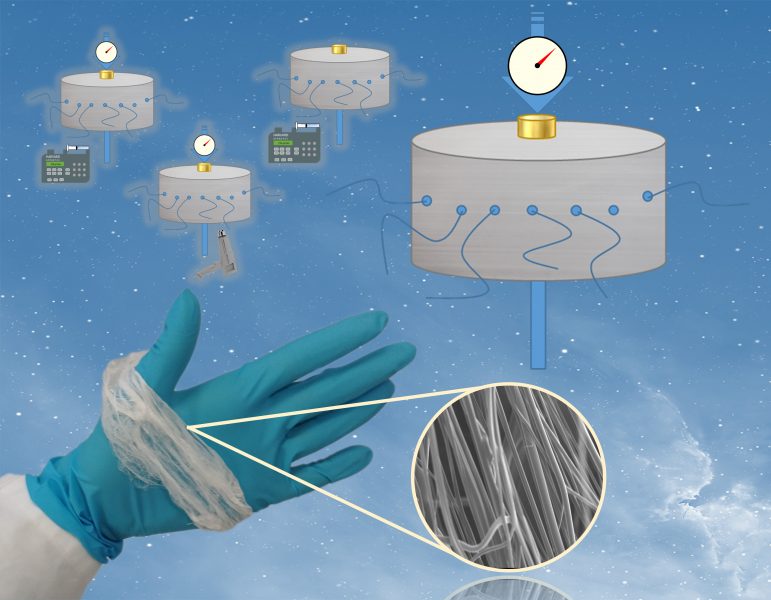

One very simple and scalable fiber forming method is pressurized gyration, where a drum containing polymer a solution is spun at high speed while gas pressure is streamed into the vessel. 5 Years after its conception, Professor Edirisinghe and co-workers have now summarized the progress made in this fascinating technique.

In pressurized gyration, fiber formation occurs as the solution is jetted through small orifices on the surface of the drum as it spins. Many polymers have been spun into fibers using pressurized gyration and its sister techniques: infusion gyration, where the solution is infused at a controlled flow rate allowing for proteins to be integrated into nanofibers, melt gyration which uses polymer melt rather than solution and pressure-coupled infusion gyration which uses pressure-flow-rotation in operation.

Pressurized gyration is a highly versatile and adaptable method and has been used to form filtration mats, drug delivery fibers and even shape memory mats. Not only is it capable of producing fibers, beads and droplets, but it can be scaled-up to industrial manufacturing levels. Fiber products can be easily aligned to generate anisotropy in properties. Future iterations of the pressurized gyration technologies will include both design and collection methods and even fiber type variations – for example core-sheath fibers.