Inkjet printing is a deposition technique that we all know very well as a process we exploit every day when using our desktop printers. The field of Printed Electronics makes extensive use of such a technique for the precise deposition of functional materials, known as inks, or more precise liquids possessing specific electrical properties, for the fabrication of a large variety of electronic devices and systems.

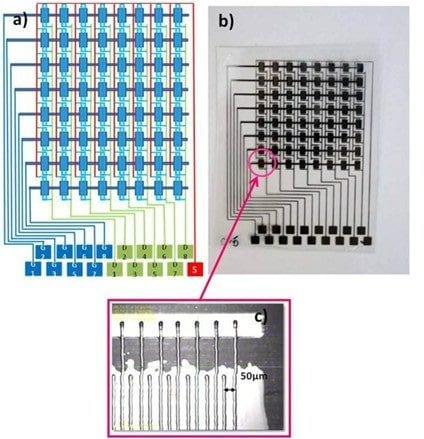

Inkjet printed arrays of organic transistors.

In their recent paper in Advanced Materials Technologies, researchers from the University Paris Diderot and Paris Sud, France, the Eurecat Technology Centre of Catalonia, Spain, and the University of Cagliari, Italy, review the recent advances of inkjet printed organic transistors. Transistors are the basic components of any electronic circuit where they are used as amplifiers – to increase the amplitude of electrical signals – or as switches – to allow or interrupt the current flow in a controlled way. Traditionally, transistors have been fabricated using rigid, highly crystalline materials, in particular silicon. Their fabrication typically requires the presence of special environments (clean rooms) with an extremely low level of pollutants, in the form of dust and other particles or chemical vapours. Moreover, silicon manufacturing requires high-vacuum as well as high-temperature processes which considerably increase the fabrication costs.

Organic transistors represent a relatively new class of electronic devices whose active material is made of (semi)conducting “plastic” molecules. These organic semiconductors are particularly attractive as they can be processed from the liquid phase and mostly at ambient conditions, hence reducing the production costs significantly. For the fabrication of organic transistors, printing techniques can be used in a similar fashion as newspapers or magazines are made. Just like an image on paper is obtained by printing a succession of different colored layers, an organic transistor can be fabricated by sequential printing different functional (electronic) inks; one layer on the top of the other layer. This revolutionary idea was first presented fifteen years ago; from that moment, much progress has been made in this field so that different types of inkjet printed organic transistors are currently available.

In their paper in Advanced Materials Technologies, Prof. Giorgio Mattana and colleagues review in a logical and subsequent manner the essential aspects of the fabrication of inkjet printed organic transistors: the ink formulation process (what composes a functional ink for the fabrication of organic transistors?), printing deposition (what are the most critical parameters to be taken into account for the devices fabrication?) and post-printing treatments (what is necessary to do after layer deposition to obtain high-performance devices?), is described in details. The most significant examples of inkjet printed organic transistors of different types, including field-effect, electrolyte-gated and electrochemical transistors, are presented as well as an overview of their applications as building blocks of more complex electronic circuits. Moreover, systems for the detection and quantification of specific external physical and chemical stimuli are discussed.

Despite the fact that some technological issues are still open, inkjet printed devices are not far from reaching their commercial phase and it is believed that, in the near future, they will be able to add new functionalities to the objects of our everyday life.

This is text was kindly provided by the authors of the review.