Sometimes, we all love to just sit back, relax, and enjoy the music, whether that’s your favorite album, favorite radio station, or recommended playlists on more modern platforms such as music streaming services.

Since the invention of the gramophone and later broadcast radio, listening to music without having to go out to a concert has been a pastime for many, and for music lovers, often the hardware is just as important as the music. The quality of speakers has come a long way since the trumpet-like gramophone, and they continue to evolve to ensure that crystal clear quality we all want from our record collection or playlists. With such evolution comes new technology and manufacturing methods, where the unlikely area of polymer science can now play an important role.

Piezoelectric polymers have several advantages compared to inorganic materials, including being lightweight, flexibility, and the possibility to use in liquid processing methods, such as (inkjet) printing.

Poly(vinylidene fluoride) (PVDF) and its copolymers are the most widely studied piezoelectric polymers and have been explored for memory devices, energy harvesters, and flexible electronics, including sensors and actuators. Also, piezoelectric polymer loudspeakers have been demonstrated.

PVDF-based loudspeakers are particular interesting due to their flexibility, simple structure and small volume, which makes them favorable for a variety of applications. However, PVDF forms a nonpolar α-phase (non-piezoelectric) with conventional preparation procedures, such as solution casting and melt cooling. A stretching process is usually applied in order to turn α-phase PVDF into β-phase (piezoelectric), which increases the cost and prevents the (large-area) application of PVDF.

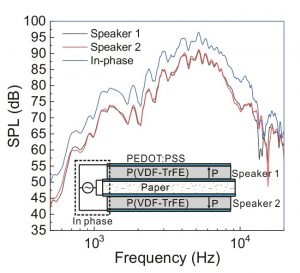

Sound pressure level of the sample with two speakers. Inset: schematic illustration of the arrangement of a sample printed with two speakers.

A team from Institute for Print and Media Technology, Chemnitz University of Technology, lead by Prof. Arved Hübler, fabricated piezoelectric polymer loudspeakers by screen printing the bottom and top electrodes on paper substrates and a piezoelectric polymer layer in between. Their work is just published as a full paper in Advanced Engineering Materials.

Printing is a convenient method for low-cost mass production. The piezoelectric polymer is suitable for printing because it forms the ferroelectric β-phase directly from solution. A sound pressure level (SPL) of about 97 dB at a distance of 1 m was obtained with two loudspeaker arrays printed on both sides of a paper substrate.

The results not only deepen the understanding of fully printed piezoelectric polymer loudspeakers, but also realize an SPL much higher than that reported in previous studies. In addition, the sample preparation can be easily transferred to an inline roll-to-roll mass printing equipment. In that way, all-printed piezoelectric polymer loudspeakers can be used for thin and highly flexible acoustic systems such as smart packaging as well as speaking books, newspapers, and posters.