Many landfills continue to be filled with unwanted electronics as new products are consumed by hungry customers wanting the latest and greatest technology. While recycling initiatives are in place to minimize the accumulation of such devices in many places, the sheer volume of electronics discarded daily makes this task seem insurmountable.

An alternate to traditional electronics has been emerging over the past decade, one that is low-cost, degradable, compostable, and made from an environmentally nontoxic substance. The answer to our need for both disposable and flexible electronics could be found in paper.

Electronics made of paper, or paper electronics, are viewed as a potentially cost-effective alternate in various applications, including in supercapacitors, sensors and actuators, diagnostic devices, and microfluidic systems, etc.

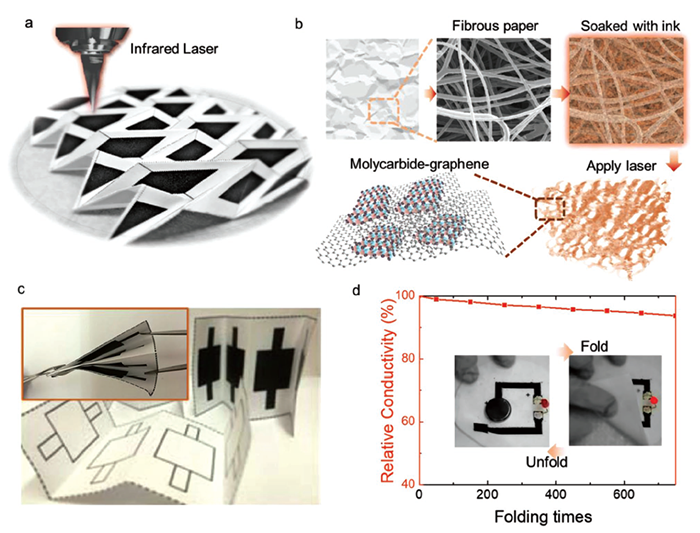

Fabricated origami structure after the direct laser-write MCG patterning process. Learn more here.

To date, the fabrication of paper electronics has seen the use of origami techniques to produce deformable and 3D structures. However, techniques to produce certain aspects of paper electronics use expensive equipment or expensive materials. Therefore, researchers continue to look for novel and inexpensive methods to fabricate these devices.

A team of researchers from the University of California Berkeley demonstrate paper-based 3D foldable devices made with multifunctional carbide–graphene composites.

The carbide–graphene composites were fabricated by converting a molybdenum ink that was deposited on a paper substrate surface to molybdenum carbide–graphene using a laser patterning technique.

The composites could be formed into functional devices for various applications. The researchers demonstrated that devices fabricated using this technique could be used as paper-based electrochemical sensors, paper-based piezoelectric generators, and as paper-based supercapacitors.

All these demonstrations show great promise and potential for the use of such paper-based devices in disposable and flexible electronics.