Batteries, fuel cells, and supercapacitors power modern society by storing and converting energy. The performance of these devices, and their potential to be integrated into small and flexible electronics, must be improved in order to keep pace with growing energy needs. Some improvements will come from creation of new materials, and some will come from development of novel methods of device fabrication.

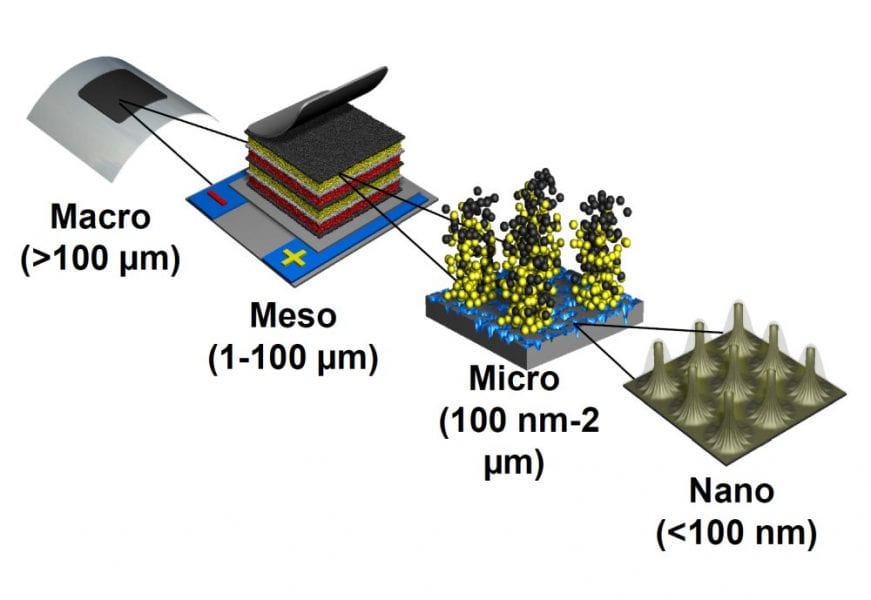

In the past several years, 3-D printing, the additive creation of three dimensional objects, has grown from a hobbyist niche to a manufacturing scale tool. A commercially available subset of these 3-D printing techniques, inkjet and aerosol jet printing, can be applied to the fabrication of batteries, fuel cells, and supercapacitors. The process begins by formulating inks containing the electrode and electrolyte materials that comprise the device. Then, after the inks are loaded into the printer, picoliter scale drops of the materials are deposited. The drops come together to form wet layers. As the layers dry, they grow one on top of another, eventually building up the full device. The potential utility of fabrication through inkjet and aerosol jet printing arises because these methods enable precise structural control over the range of length scales (micro, meso, and macro) that affect energy, power, safety, and device integration.

As presented in this Review by L. J. Deiner and T. L. Reitz, recent research demonstrates progress towards realizing the advantages of inkjet and aerosol jet printing of energy storage and conversion devices. At the same time, many scientific and engineering challenges remain. These challenges include formulating environmentally friendly inks, developing techniques for simultaneous drying of dissimilar printed layers, and improving methods to control the 3-D structure of deposited layers. When these and other challenges are tackled, inkjet and aerosol jet printing may provide cost effective routes for manufacture of the next generation of batteries, fuel cells, and supercapacitors.