The interest in additive manufacturing techniques has increased rapidly during the last years. In the Fused Deposition Modeling (FDM) process thin strands of thermoplastic material are extruded and arranged next to or upon each other. In that way finally the desired part is formed. The manufacturing equipment required is comparatively cheap and easy to handle. Thus, the use of FDM in both industrial and private areas grew significantly.

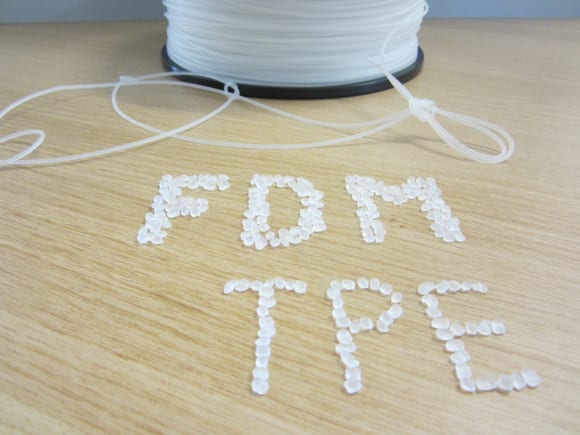

A research project examines elastic materials for FDM processing. Source: SKZ.

In the same time the range of available filaments from different materials was considerably broadened. However, soft and elastic materials for FDM processing are still very limited. A recently started research project aims at the development of materials based on thermoplastic elastomers (TPE) that can be shaped into filaments suitable for FDM processing.

In parallel, compatible hard components for two-component parts (hard/soft combinations) are investigated. Additionally, hard- and software of the FDM printer are adjusted for the processing of soft filaments and the production of two-component objects. Engineering office Achatz & Grauel GmbH, filament producer Herz GmbH, and the SKZ are cooperating in this project to complete the tasks.