Printing technologies have come a long way since the Gutenberg press. Advancements in both printing concepts, ink formulations and equipment design have added printable dimensions and opened up the technique to a huge variety of materials. They have also enabled finer and finer control over the size and shape of the printed items. Of particular interest to the fields of biomanufacturing and living electronics, new methods and technologies have enabled the printing of living, 3D, cellular structures.

The key to creating a living structure is of course to ensure that the printed cells remain viable – that is, that they live beyond their configuration or depos ition onto a substrate. Printing techniques must also offer fine structural control at a low cost and with good throughput – practical concerns which do not often coincide with high cell viability.

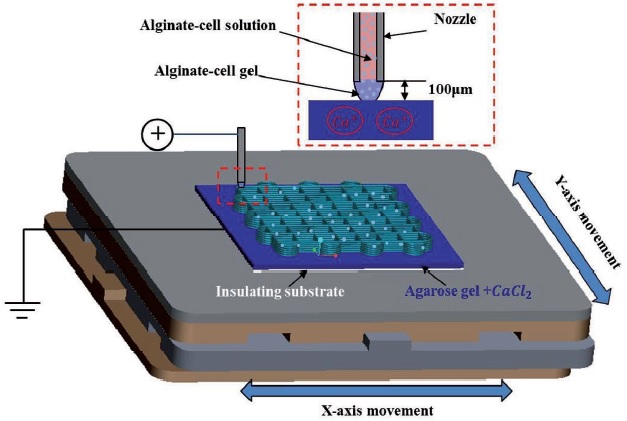

An advance upon the current inkjet, extrusion, and laser-assisted techniques is a new electro-hydrodynamic printing method developed by a group from Xi’an Jiaotong University, China. Their process uses an insulating substrate, reducing the current required by several orders of magnitude and achieving a printed hydrogel filament width down to about 82 micrometers. Multiple layers of different hydrogels can be printed to generate complex structures under what the researchers call ‘cell-friendly conditions’, with cells remaining highly viable in vitro for the 7 days they were studied.

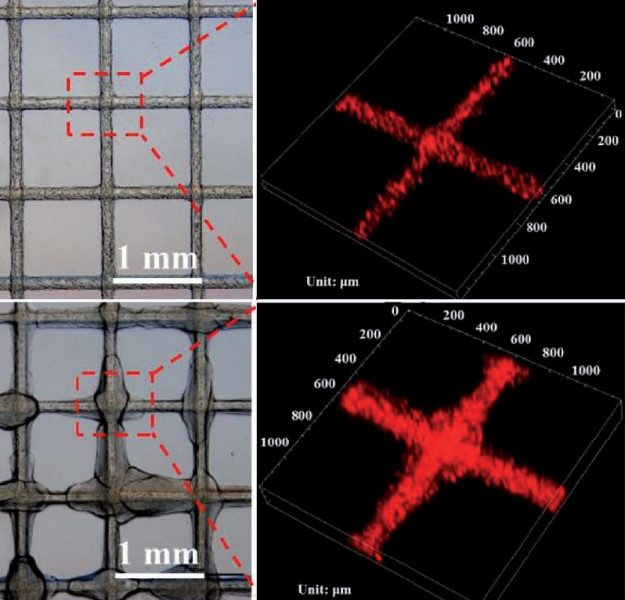

Printed filaments with 20 layers (bottom) show more spreading than those with 5 layers (top).

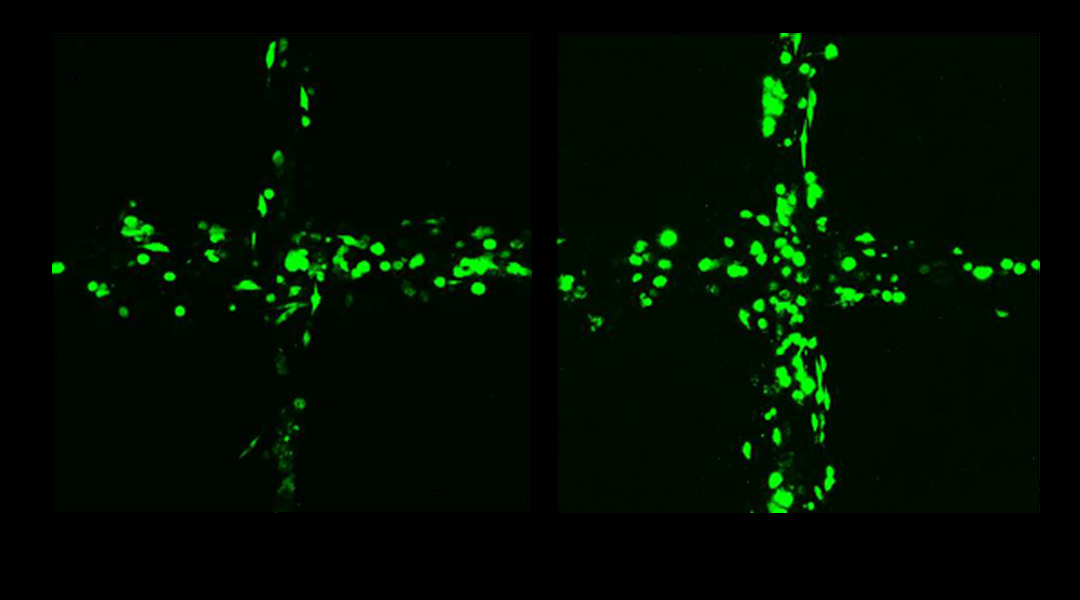

The morphology and distribution of the cells within the printed regions was also monitored over this time. Though there was little change over the first day, cells gradually spread within the hydrogel filaments over the course of the study.

To allow the creation of even more stable multilayered structures, they are seeking a new method of crosslinking to replace the more common diffusion-based mechanism to accelerate the ‘setting’ of the gel. With this step, the researchers believe that their technique will enable the formation of highly viable 3D cellular structures wanted for tissue engineering and nanomedical applications.

See the details of their new printing method and supporting videos in their Communication in Small.