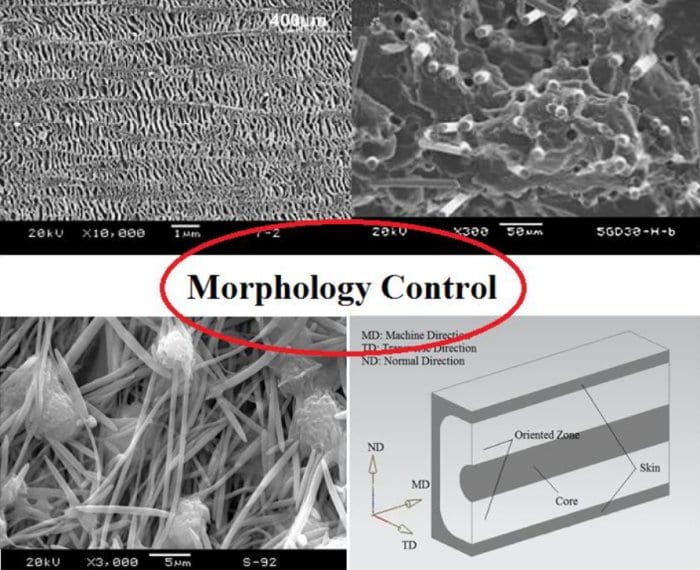

The performances of products are mainly determined by their composition and internal structure. On the other hand, internal structure depends, to a great extent, on external fields that are imposed during processing. Therefore, by using unique external fields, such as shear, extension, vibration and magnetic fields, etc., it is possible to control the morphology and microstructure of samples, and then to improve product performance such as mechanical, barrier, or electrical properties.

Based on this concept, several new processing technologies have been proposed and intensively studied in recent years.

In their present review, Xue-Qin Gao et al. (Sichuan University, Chengdu) present a summary of four different types of new processing methodologies, namely shear controlled orientation in injection molding, vibration-assisted injection molding/extrusion, rotational extrusion and in situ microfibrillation/formation. These technologies allow to achieve structural and morphological control and performance improvements without modifying the original polymer systems.

These nonconventional process technologies have a significant impact on both experimental study and industrial production, while it is still challenging to bring the benefits of these technologies to full commercialization.