Silkworm fibers have been used as textile materials for more than 7000 years in China. Now silk protein materials are evaluated as one of the most promising functional materials in the 21st century, due to their emerging applications in tissue engineering, flexible photonics/electronics, drug delivery, catalysis, biological analysis, etc. It has been recognized that the Bombyx mori silk, as a type of excellent bio-flexible material, will be far more important in the above applications than the traditional textile industries.

As flexible photonics/electronics industries are going to take over the traditional industries, Bombyx mori silk will serve as a crucial material due to its capability of functionalization and re-engineering. This is apart from its inherited excellent mechanical, optical, biocompatible, thermal properties, which offer unconventional interfaces to soft and curved biological systems.

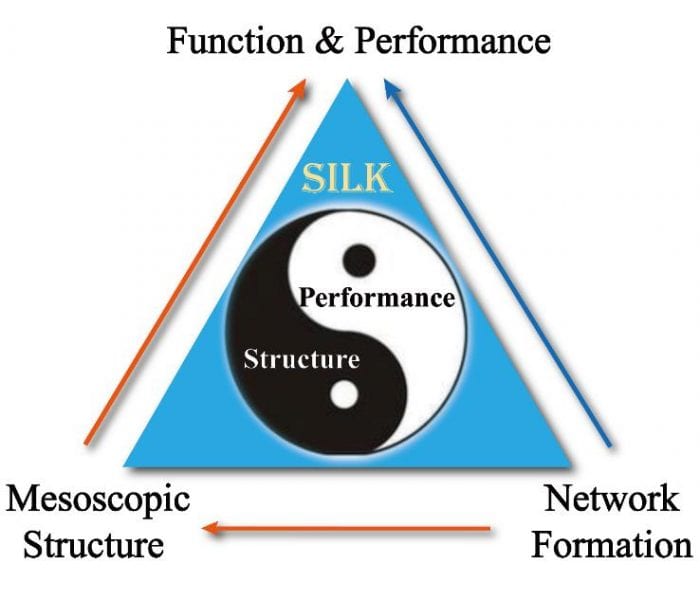

As typical natural soft materials, Bombyx mori silk materials have 3D fibrous network structures which determine the macroscopic performance. In other words, some specific performance of silk materials can be programmed by (re-) engineering the hierarchical structure at the mesoscale. In this regard, the ability to control the mesoscale structures and architectures of silk materials turns out to be particularly important in order to fabricate the materials for the designated applications.

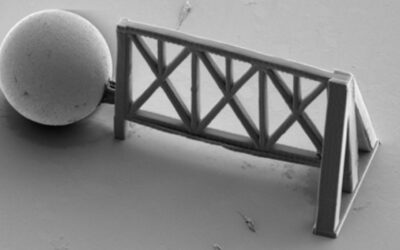

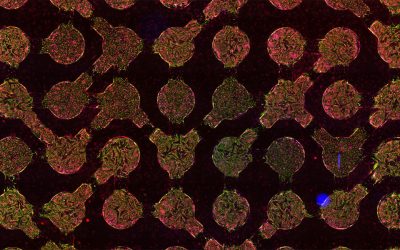

In order to achieve the effective manipulation of the mesoscale structures, a detailed understanding of the formation process of silk materials is indispensable. Recently, Prof. Liu Xiang Yang’s team has identified the mechanism of silk materials formation: it is governed by nucleation, a mechanism similar to the control of ice formation. Based on this mechanism, they put forward a novel strategy to effectively manipulate macroscopic performance of silk materials by tuning the mesoscopic network structures. Briefly, with the aid of foreign substrates – the mono-dispersed colloidal particles – the structure of crystal networks can be tailor-made to acquire a different performance. For instance, they can tune the structure to obtain tougher silk fibers or to acquire more extensible films, by simply controlling the nucleation. Therefore, the nucleation mechanism turns out to be very important in the development of key fabrication technologies for high performance soft materials (strong fibers) and flexible devices.

In order to achieve the effective manipulation of the mesoscale structures, a detailed understanding of the formation process of silk materials is indispensable. Recently, Prof. Liu Xiang Yang’s team has identified the mechanism of silk materials formation: it is governed by nucleation, a mechanism similar to the control of ice formation. Based on this mechanism, they put forward a novel strategy to effectively manipulate macroscopic performance of silk materials by tuning the mesoscopic network structures. Briefly, with the aid of foreign substrates – the mono-dispersed colloidal particles – the structure of crystal networks can be tailor-made to acquire a different performance. For instance, they can tune the structure to obtain tougher silk fibers or to acquire more extensible films, by simply controlling the nucleation. Therefore, the nucleation mechanism turns out to be very important in the development of key fabrication technologies for high performance soft materials (strong fibers) and flexible devices.

This new strategy will lay down the foundation and will be the cornerstone for future research in soft materials functionalization and flexible devices. Moreover, this research is related to the “crystallization” of proteins, which means it will have an important implication on the understanding and control of ageing diseases.