The Fukushima nuclear reactor accident has increased demand for efficient, non-toxic, and lightweight gamma radiation shielding materials, as its absence caused serious delays in managing the situation, and conventional lead-based shielding materials introduce adverse health and environmental effects. Researchers from the Korea Atomic Energy Research Institute (Kim et al.) have now offered a solution to the problem of how to produce lightweight and reliable garments or sheets for protection against gamma and X-ray radiation. The group has suggested the use of nanotechnology for preparing such materials, as it can greatly enhance both the material properties and the shielding efficiency.

The Fukushima nuclear reactor accident has increased demand for efficient, non-toxic, and lightweight gamma radiation shielding materials, as its absence caused serious delays in managing the situation, and conventional lead-based shielding materials introduce adverse health and environmental effects. Researchers from the Korea Atomic Energy Research Institute (Kim et al.) have now offered a solution to the problem of how to produce lightweight and reliable garments or sheets for protection against gamma and X-ray radiation. The group has suggested the use of nanotechnology for preparing such materials, as it can greatly enhance both the material properties and the shielding efficiency.

The team constructed a lattice-based MCNP model to simulate the relationship between tungsten particle size and gamma-energy-dependent attenuation. They observed the size effect increases as the gamma energy decreases, while it decreases and disappears all energies higher than ~1 MeV. They also verified this concept experimentally by measuring the gamma attenuation using three different energies (~0.3 MeV to ~1.2 MeV) for both nano- and micro-systems.

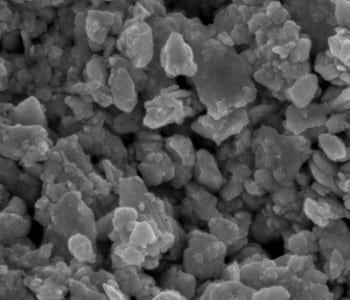

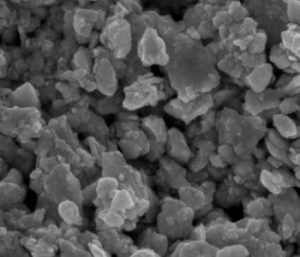

More importantly, they developed a simple but efficient preparation method for such materials. In-situ pulverization of micro-tungsten powder with polyethylene powder using high energy ball milling produced nano-tungsten powder, the surface of which is encapsulated by PE. Based on this method, a nano-tungsten/polyethylene dispersed polymer nanocomposite was prepared using a conventional polymer extruding process, which is readily applicable to mass production. The researchers believe that their nano-tungsten-containing products for shielding X-ray and gamma radiation – including a full body apron and a thyroid guard – are the first commercially available.