In their beautifully written article for Advanced Sustainable Systems, researchers from Clemson University, USA, describe the use of agricultural and petrochemical wastes to manufacture composites that are themselves readily recyclable.

Exploiting the reversibility of sulfur–sulfur single bonds, they take an interpenetrating 3D network of methallylated cellulose and covalently cross-link it with chains of polymeric sulfur in an inverse vulcanization process. The generated composites have a high flexural strength, comparable to that of commercially available Portland cement. The cellulose–sulfur composites can then be used to backfill the pores of such structural materials, reducing their water uptake and rendering them resistant to degradation in acidic environments.

Industrial wastes are used to form composites that outlast current building materials in acidic conditions.

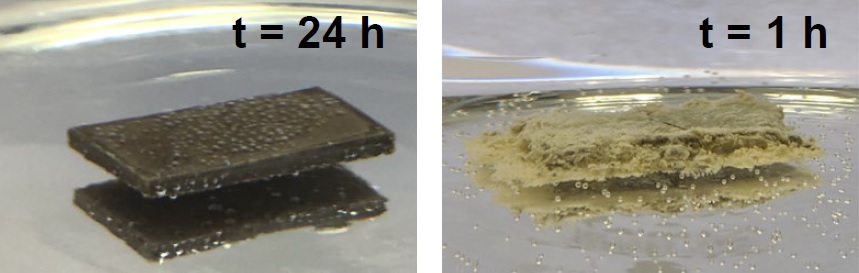

As shown in the paper, actual Portland cement barely lasted an hour in 0.5 M H2SO4, while the new composite remained unaffected after several days’ exposure. When the cement was back-filled with composite, it managed to retain 95% of its strength after 24 hours submerged in the acid.

As the composites are thermoplastic, they could also be repeatedly melted and re-cast into silicone moulds over many cycles.

The ingredients for these composites come from what the researchers refer to as “underappreciated, sustainably-sourced feedstocks”, quoting 60 million metric tons of elemental sulfur (S8) produced each year as a waste product of the petroleum refining process, which may not itself be environmentally friendly but which demonstrably can be used to make other industries greener. Cellulose can be sourced from agricultural wastes, the annual 5 billion metric tons of which is expected to grow along with the world’s population.

As such, reducing this waste by turning it into a useful resource is a critical step to mitigate the harm caused by these industries, but that’s just the first advantage in the cycle of more sustainable practices being enabled here: as indicated above, these thermoplastics can be re-cast and used again, and they render other industrial materials more robust, extending their usable lifetimes and reducing the need for the production of replacement parts.

Interested in more content on waste reduction and sustainable practices?