The sun is a powerful source of heat and light, but this energy may also be destructive toward materials, including organic and polymer solar cells. Photo-oxidation is usually the problem, but in the absence of corrosive conditions, intense illumination still leads to “burn-in”—a rapid decrease of device performance linked to rapid degradation of electron transport.

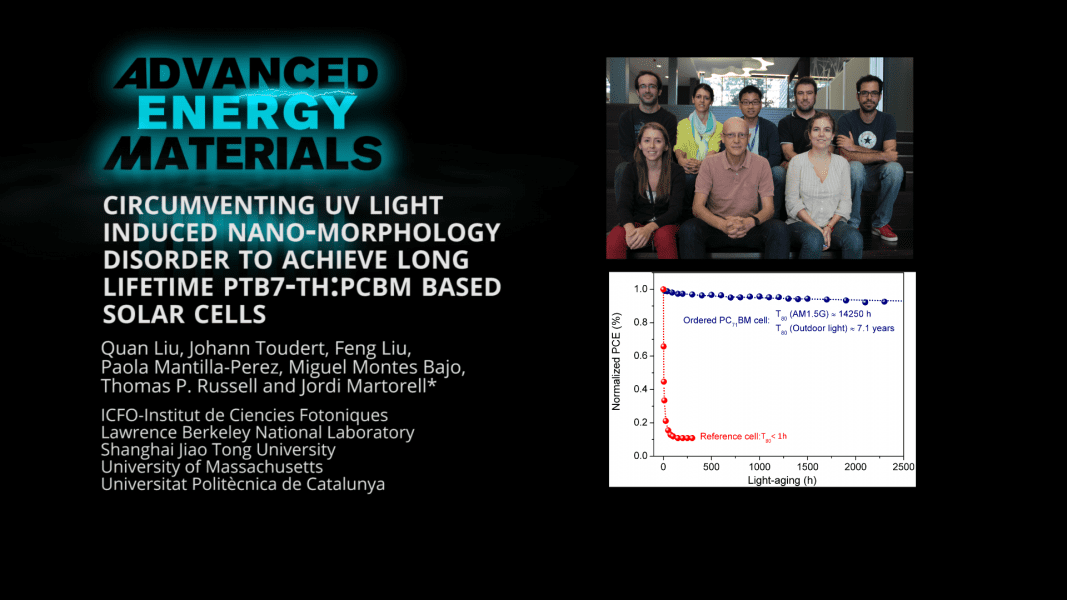

In their full paper in Advanced Energy Materials, Jordi Martorell and co-workers propose ways to achieve a long lifetime of polymer solar cells by addressing the issue and mechanism of UV-induced nano-morphology disorder.

The authors turned to solution-processable active materials: PCBM (a fullerene derivative) as the electron acceptor layer and PTB7-Th as a high-performance photovoltaic polymer, with a morphology comprised of nanoscopic domains of each of the components for fabrication of the devices in the inverted cell configuration.

To overcome UV-induced degradation of exciton diffusion and charge mobility, and to increase device lifetime, the authors used thermal annealing prior to light soaking to increase the active layer’s crystalline order. Blend composition (the ratio of donor to acceptor) was adjusted, and 1,8-diiodooctane (DIO)-free cells obtained for a 1:2 weight ratio showed the best power conversion efficiency of 9.6%. Upon thermal annealing, DIO-free cells exhibited excellent short-circuit current stability. Grazing incidence wide-angle X-ray diffraction measurements prior to and after annealing confirmed an increase in ordering in the annealed blends.

The performance of the annealed cells was monitored under continuous light exposure up to 2300 h, indicating retention of more than 92% of their initial power conversion efficiency (PCE), and predicting a T80 lifetime of more than 7 years under full sunlight illumination. An impressive 10-year lifetime could be forecast for vertical applications. Along with the high PCE, this suggests that the strategy may be applied to future solar window technologies.

To learn more details about this study, please visit the Advanced Energy Materials homepage.