Water covers over 70% of the Earth’s surface and is vital to support life. In the nuclear industry, decomposition of water into hydrogen and oxygen can occur inside waste containers, leading to explosion. Removal of hydrogen gas is necessary to address this issue.

In their paper in Advanced Functional Materials, Dr. Denisse Ortiz-Acosta and colleagues from Los Alamos National Laboratory fabricate and evaluate 3D silicone materials for hydrogen removal.

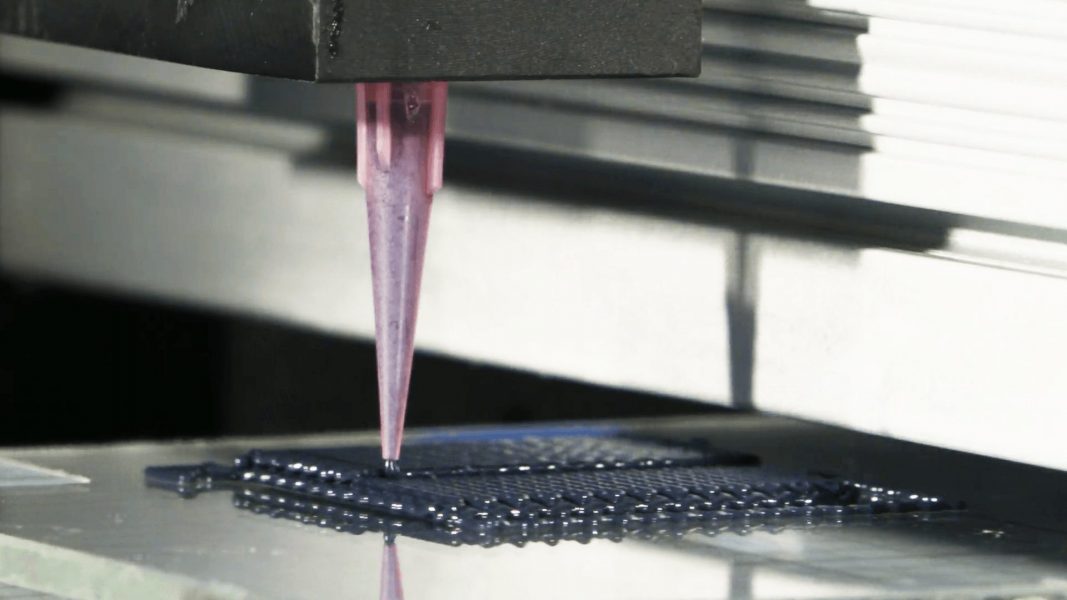

Getters, materials used to aid hydrogen removal, were fabricated using a 3D printer. Additives were incorporated into a silicone resin to optimize the rheological properties, getter capacity, and pot life.

The printed composite exhibited a lattice structure, providing a higher specific surface area than cast samples, which could aid faster hydrogen diffusion to unsaturated getter sites.

Resin formulation and cure temperature were found to have a significant effect on the hydrogen capacity and hydrogenation kinetics of the getter composites.

Overall, this 3D-printed getter composite shows promise for hydrogen removal.

To find out more about these 3D-printed composites with hydrogen getter capabilities, please visit the Advanced Functional Materials homepage.