Researchers from North Carolina State University have developed a new nanolithography technique that is less expensive than other approaches and can be used to create technologies with biomedical applications.

“Among other things, this type of lithography can be used to manufacture chips for use in biological sensors that can identify target molecules, such as proteins or genetic material associated with specific medical conditions,” says Dr. Albena Ivanisevic, co-author of a paper describing the research. Ivanisevic is an associate professor of materials science and engineering at NC State and associate professor of the joint biomedical engineering program at NC State and the University of North Carolina at Chapel Hill. Nanolithography is a way of printing patterns at the nanoscale.

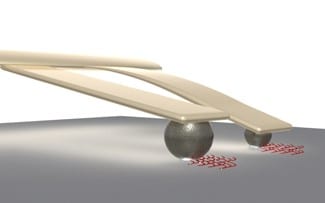

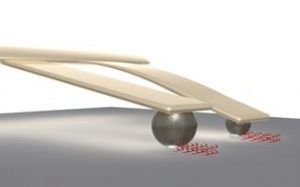

This technique uses no electronic components to bring the cantilevers into contact with the substrate surface.

The new technique relies on cantilevers, which are 150-micron long silicon strips. The cantilevers can be tipped with spheres made of polymer or with naturally occurring spores. The spheres and spores are coated with ink and dried. The spheres and spores are absorbent and will soak up water when exposed to increased humidity.

As a result, when the cantilevers are exposed to humidity in a chamber, the spheres and spores absorb water – making the tips of the cantilevers heavier and dragging them down into contact with any chosen surface.

Users can manipulate the size of the spheres and spores, which allows them to control the patterns created by the cantilevers. For example, at low humidity, a large sphere will absorb more water than a small sphere, and will therefore be dragged down into contact with the substrate surface. The small sphere won’t be lowered into contact with the surface until it is exposed to higher humidity and absorbs more water.

Further, the differing characteristics of sphere polymers and spores mean that they absorb different amounts of water when exposed to the same humidity – giving users even more control of the nanolithography.

“This technique is less expensive than other device-driven lithography techniques used for microfabrication because the cantilevers do not rely on electronic components to bring the cantilevers into contact with the substrate surface,” Ivanisevic says. “Next steps for this work include using this approach to fabricate lithographic patterns onto tissue for use in tissue regeneration efforts.”

Source: North Carolina State University