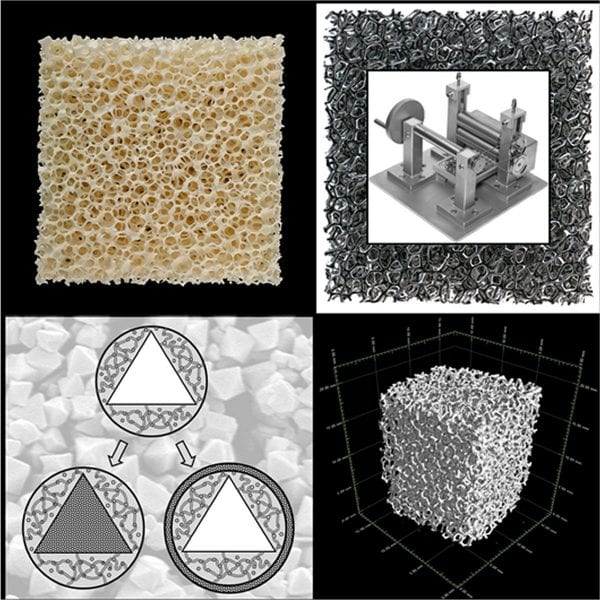

Reticulated ceramic foams are used in a wide range of applications such as filters, catalyst supports, lightweight materials, energy absorptions materials, or as scaffolds for tissue engineering as the most common ones. Based on gaseous foaming processes of polymers, a stochastic distribution of closed pores is obtained. By reticulation processing thin foam windows are removed between cells turning a closed cell into an open cell structure.

These foams are used as template for porous ceramics manufacturing: With different processing approaches, for example, with dip coating of a ceramic slurry and a subsequent (multistep) thermal treatment ceramic reticulate foams are obtained. A variety of material properties strongly depend on the cell and strut size, as well on material composition. Functionalization of ceramic foam surfaces (outer surface functionalization), for example, with zeolites or nanosized aggregates lead to an increase of the specific surface area or provides catalytic or heat storage functionality. Filling of struts (inner surface functionalization) may lead to improved mechanical stability or may provide functionalities such as electric conductivity.

In this recently published article by Michael Scheffler et al. reticulated porous ceramics are reviewed resulting from a manufacturing process described first in a patent in 1963, and granted to Schwartzwalder and Somers. The focus is set to the manufacturing process and its modifications and resulting slurry properties, to subsequent modification strategies and to characterization methods of materials properties. It may help the reader to identify future research potential.