Scientists in the Plant Biomechanics Group Freiburg (PBG) and Freiburg Materials Research Center (FMF) at the University of Freiburg in Germany as well as engineers from E.G.O.-Group (E.G.O.), have developed a biomimetic flow channel module that facilitates continuous process water analysis in washing machines. Their results were recently published in Advanced Intelligent Systems.

Washing machines have been identified as an important leverage point to reduce energy and material consumption that at present can be described as black boxes that are controlled by a few sensors in combination with the washing program selected by the user.

Recent sensor technology has allowed the gathering and evaluation of information on various substances and parameters, such as detergent components, microscopic and nanoscopic fibers, pH, and temperature (among others), in order to automate and improve washing processes.

These require flow profiles with specific hydrodynamic characteristics, with the most important criteria being: the separation of the representative target substances from the main flow and their diversion to the analysis unit; the generation of low, almost constant flow velocities; the maximization of the target-specific residence times to guarantee sufficiently long measuring times; and the generation of the desired flow type (laminar vs. turbulent flow).

Inspiration was taken from the olfactory organ of the smalleye hammerhead shark (Sphyrna tudes), which is able to detect and precisely follow even the smallest amounts of odorants in their pursuit of constantly moving and reorienting prey. In order to protect their sensory epithelium from damage caused by excessive flow at very high swimming speeds, these sharks have evolved a complex internal passive regulation mechanism.

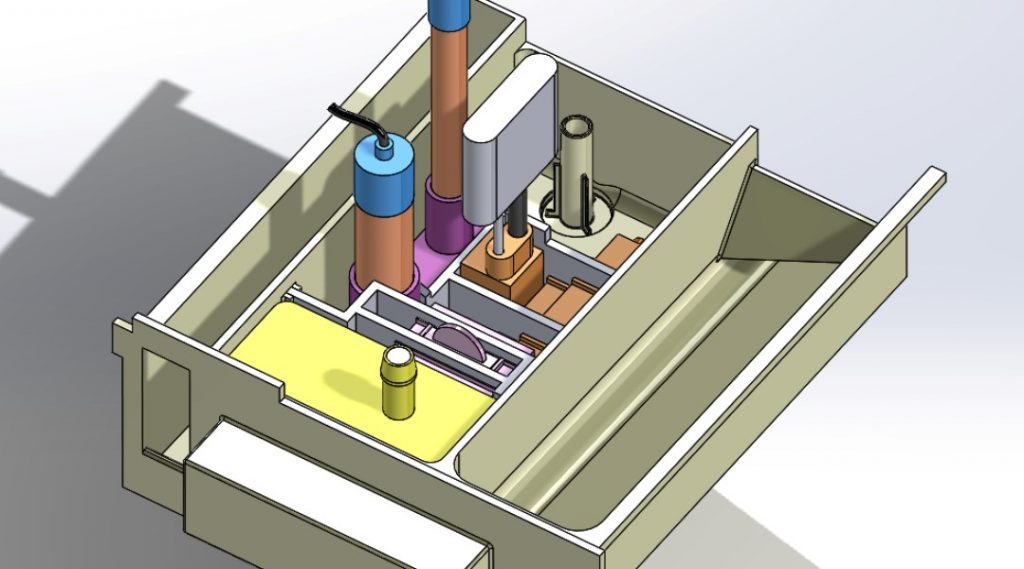

Following a biomimetic approach combined with 3D-printing methods, this mechanism was abstracted and transferred into three iteratively developed flow channel modules intended to be integrated into the washing machine’s detergent drawer. The module’s intrinsic flow profile is passively determined by the fluid’s inflow velocity and the channel geometry, and it comprises a sensor zone whose hydrodynamic characteristics are suitable for the use of a wide variety of sensor technologies.

The fact that the detergent drawer of a washing machine represents an interchangeable unit and that 3D-printing costs continuously decrease while corresponding printing speeds increase, make this solution an easy to implement and therefore cost-efficient solution towards a resource-efficient “one-button” washing machine.

Kindly contributed by the authors