Wearable electronics that mimic skin, both mechanically and in its sensing properties, will be a vital part of the future technologies that will be integrated into our everyday lives. This ‘electronic skin’ (e-skin) will need to be as robust and durable as normal human skin to withstand repeated use and mechanical damage.

Self-healing polymers with electronic properties have been reported as potential candidates for e-skin. However, most common self-healing polymers are based on weak dynamic bonds, which easily succumb to breakage. This breakage typically occurs along small notches or defects in the surfaces of the self-healing polymer hydrogels. Moreover, these inferior self-healing polymers tend to exhibit low mechanical toughness and large deformation.

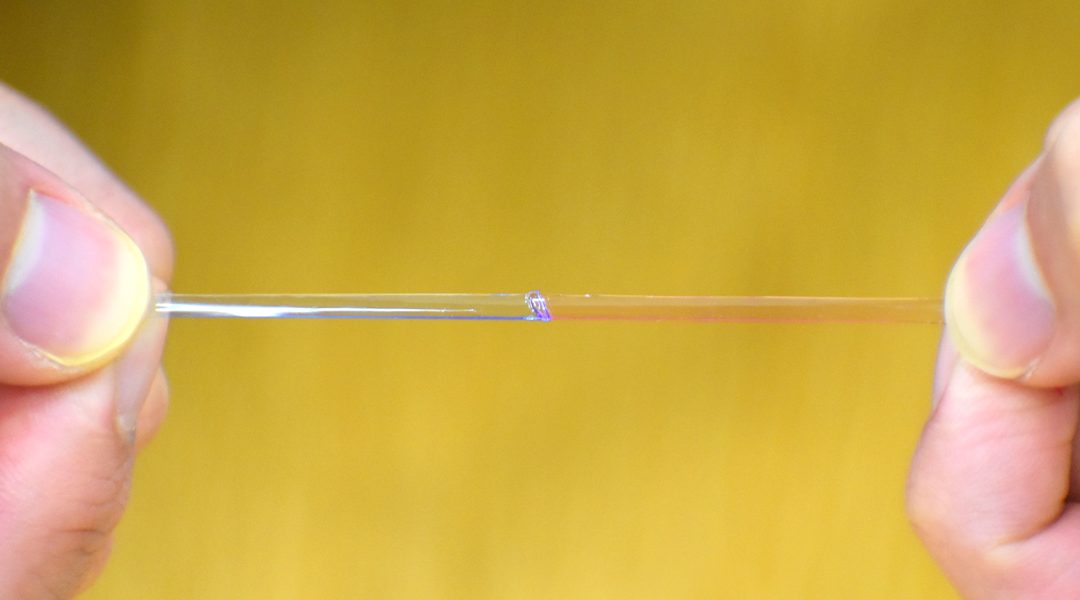

The self-healing elastic polymer network exhibits high fracture energy and defect-insensitivity, and is moldable and stackable which facilitates the construction of stretchable 3D objects.

By employing supramolecular chemistry, a tough elastic material was developed. The researchers state that, “Our material has multiple important properties: 1) high stretchability (good mechanical strength, 2) extremely high fracture toughness, and 3) underwater self-healing. These features enabled us to fabricate fully self-healing tough electronic skin. After severe mechanical damages such as scratching or even completely cutting, our e-skin can heal itself even under water like ‘Wolverine’ and operate.”

The unique polymer design is the foundation to form tough, self-healing crosslinked networks by exploiting multistrength hydrogen bonding interactions. This toughness leads to complete recovery of mechanical strength after mechanical damage. The self-healing can also occur under water.

The integration of Liquid Metal (EGaln) as an electronically conductive layer was achieved, and recovery of mechanical and electrical performance after a complete cut of the polymer was demonstrated.

Future challenges for researchers, include improving the thermal stability of the material; nevertheless, the current proposed material can retain its exceptional mechanical properties up to 60°C. The development of e-skin that incorporates multiple sensors and displays would bring us one step closer to the a future where wearable electronics are normal part of our everyday lives.