Flexible transparent electrodes are essential components of wearable optoelectronic devices. Such electrodes are required to have versatile features such as superior optoelectronic properties, lightweight portability, low cost, and mechanical flexibility.

So far, indium tin oxide (ITO) is the most often used material for the transparent electrode, but its high film fragility as well as high materials and fabrication costs are inevitable barriers for certain commercial applications. Although alternatives have been achieved, instinctive mechanical properties limit their future commercialization compared with polyethylene terephthalate (PET)/ITO. In addition, the preparation of transparent electrodes would be preferably based on printing methods, as these can be easily upscaled and integrated in a roll-to-roll process.

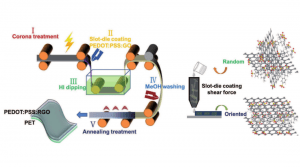

The five steps in the roll-to-roll processes for PEDOT:PSS:RGO films (left) and the structural change of PEDOT:PSS composite after slot-die coating (right).

Professor Yiwang Chen and colleagues from the College of Chemistry at the Nanchang University, China, report in an article in Advanced Materials Technologies, their results on an oriented graphene oxide in a poly(3,4-ethylenedioxythiophene):polystyrene sulfonate (PEDOT:PSS) matrix via the shear force of slot-die printing during a roll-to-roll process.

The hydroiodic acid post-treatment can remove the insulating content of the conductive polymer and reduce the graphene oxide to enhance the conductivity and at the same time improve the transmittance. As a result, the flexible transparent electrodes demonstrate a remarkable flexural endurance, even under extreme bending, and were used in real polymer solar cells. Using a roll-to-roll printing technology the electrodes can be produced for 2.8$ per square meter.

This flexible electrode in combination with roll-to-roll technologies provides a novel strategy for higher performance and cheaper cost manufacturing for future wearable photoelectric devices.

For further reading, please see the original article here in Advanced Materials Technologies.