Titanium in its unalloyed condition is as strong as some steels, but 45% lighter. However, this is not the main reason why titanium finds widespread use in implants and biomedical devices. It also has excellent corrosion resistance, bio-compatibility, and lack of magnetism.

Titanium in its unalloyed condition is as strong as some steels, but 45% lighter. However, this is not the main reason why titanium finds widespread use in implants and biomedical devices. It also has excellent corrosion resistance, bio-compatibility, and lack of magnetism.

Microporous titanium provides two additional advantages for implant applications: first, it reduces the stiffness of the material, thus reducing stress shielding, and, second, it improves implant anchorage by allowing bone ingrowth.

Furthermore, titanium which is made of a microlattice or truss structures exhibits an outstanding combination of low density, high strength and stiffness, and good damage tolerance. To date, production methods for this micro-architectured titanium have focused on replication precision casting, sintering of stacked wire arrays, and as selective electron beam or laser sintering of Ti powders.

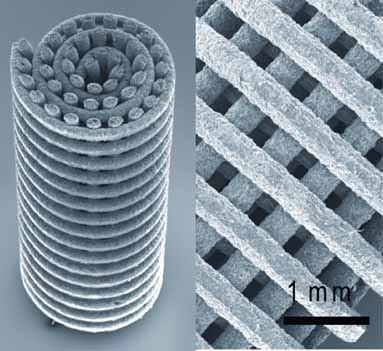

Recently, a group of researchers from the USA, Japan, and Korea introduced a new method for creating 3D micro-architectured Ti structures. They produced titanium scrolls by printing titanium hydride lattices composed of two orthogonal layers of ink filaments, which are then rolled into cylinders and finally reduced to titanium upon partial vacuum sintering.

This method enables high shape versatility, and the ability to control local geometry, as well as scalability to larger structures. In an experimental study the group used this novel approach to produce reticulated Ti scrolls and characterized their microstructural and mechanical properties.

The researchers formulated inks for direct-write assembly that consisted of titanium hydride powder and a copolymer with different particle size and distribution. Before and after heat-treatment, the scrolls are weighed and their diameter and height are measured to quantify changes in their diameter and calculate their total porosity. Uniaxial compressive tests were performed, strain and hardness determined.

The study shows that these reticulated architectures exhibit an attractive combination of stiffness, strength, and ductility. Orthogonal filaments within the double-layered titanium mesh are well bonded with clearly defined sintering necks. Micropores are present in the filaments of all scrolls, with their volume fraction decreasing as the particle size decreases, as expected from their improved sinterability.

The researches conclude that the novel process developed for titanium is applicable to other metals or even to a variety of sinterable ceramics such as oxides, resulting in ceramic scrolls. There is, however, still a long way to go.