Inspired by Marvel Comics’ Spider-Man — everyone’s favorite superhero except perhaps J. Jonah Jameson — researchers at Tufts University have developed real-life “web shooters.”

Before you start planning a web-swinging excursion through New York City or webbing up criminals at the scene of a crime, please consider this technology, detailed in a paper published in Advanced Functional Materials, may have been inspired by that kind of rewarding action but it is in its very early stages.

The current web-slinging set up consists of a needle that shoots a fluid that immediately solidifies as a strand that can adhere to objects, allowing the developers at Tufts University’s, aptly named the “Silklab,” to lift them.

“As scientists and engineers, we navigate the boundary between imagination and practice. That’s where all the magic happens,” said Fiorenzo Omenetto, Frank C. Doble Professor of Engineering at Tufts University and director of the Silklab in a statement. “We can be inspired by nature. We can be inspired by comics and science fiction.

“In this case, we wanted to reverse engineer our silk material to behave the way nature originally designed it and comic book writers imagined it.”

The amazing… moth man?

Long before 1962, when Peter Parker first created his homemade web fluid and strapped on his web shooters in Amazing Fantasy number 15, nature had perfected the art of producing webs, tethers, and cocoons. Insects and arachnids, including spiders, ants, wasps, bees, butterflies, moths, beetles, and flies, can produce silk strands and structures during their lifecycles.

Of course, this is most associated with spiders who weave silk threads into intricate webs to trap food, to “fly” by floating on long strands, allowing the wind to grab them, and to communicate with each other. Male nursery spiders even use their silk to wrap gory insect “gifts” for prospective mates.

When considering its strength-to-density ratio and comparing on a size-to-size basis, spider webs are stronger than steel and yet are highly elastic, capable of stretching to five times their initial length. Spider silk is also biodegradable and biocompatible with humans.

Tougher than Kevlar, it is little wonder that humanity has proposed a diverse range of technological applications for spiderwebs. That includes bulletproof clothing, surgical stitching, ropes, nets, seat belts, parachutes, and even rust-proof paneling for boats and cars.

However, the Silklab team didn’t turn to spiderweb for their initial “web-slinging” devices. Instead, they chose to experiment with silk derived from the cocoons of moths.

The researchers took this silk and boiled it in a solution to extract its building block proteins, fibroin. The resultant solution can then be deployed through a fine needle, solidifying into a thread when it hits the air. Like some of the best comic book superhero origin stories, the team’s web-spinners began with a stroke of good fortune.

“I was working on a project making extremely strong adhesives using silk fibroin, and while I was cleaning my glassware with acetone, I noticed a web-like material forming on the bottom of the glass,” Marco Lo Presti, research assistant professor at Tufts, told Tufts Now.

Peter Parker makes it look easy, but to translate this good fortune and chance discovery into a replication of Spider-Man’s web shooters, the team set out on an arduous journey of gradual improvement.

Spinning good luck into spider webs

Silklab scientists initially found that when their fibroin solution was exposed to organic solvents like ethanol and acetone, it would form a semi-solid hydrogel over a period of a few hours.

They then discovered that adding dopamine, the chemical messenger “feel-good” hormone also used in the production of adhesives, meant the fibroin solution would solidify almost instantly on contact with air.

This is because the dopamine acted to pull water away from the silk, expediting the transformation from liquid to solid. Dopamine is also used by barnacles to create the fibers that allow them to tenaciously adhere to the hulls of ships so it also adds adhesiveness to the mix.

When introduced to air, quick mixing meant that the solution transformed into fibers with both high tensile strength and stickiness. The team could vary the bore size of the needle to create threads varying in thickness from around half a millimeter to a tenth of a millimeter, about the thickness of a human hair.

Spinning their webs in the air, the Silklab team added an acetone layer that coats the solution as it leaves the tip of the needle, which kicks off the transformation to solid. This acetone layer then evaporates as the silk thread travels, allowing these artificial web fibers to adhere to a target.

The scientists boosted the tensile strength of the solution by 200 times with another invertebrate-related ingredient, chitosan, a fibrous sugar found in the exoskeletons of shellfish like crab, lobster, and shrimp. They also boosted the stickiness of the threads by around 18 times by adding a borate buffer.

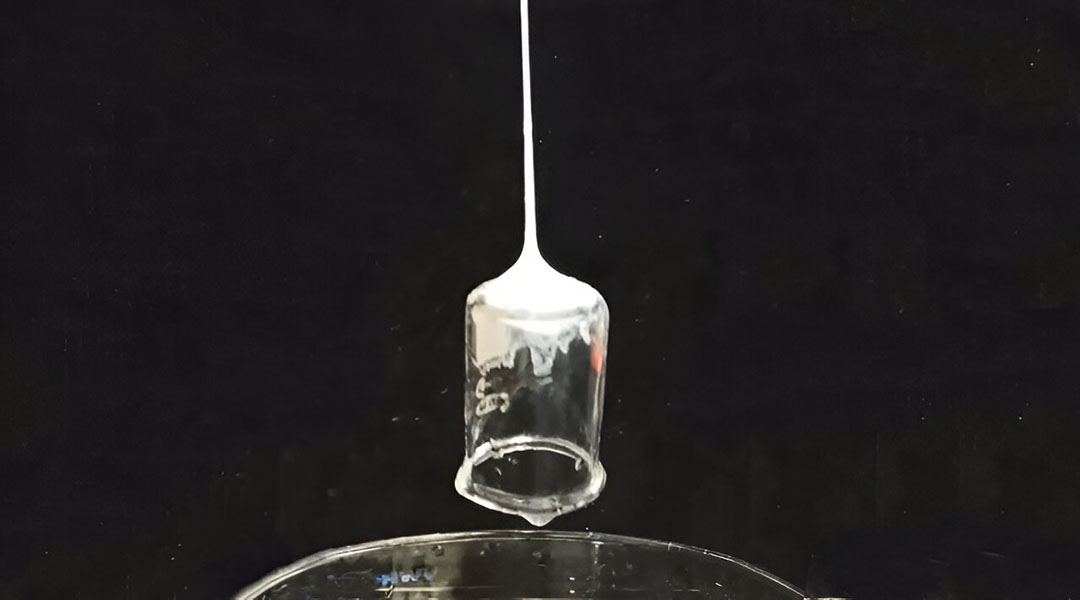

The result was a device that can shoot an adhesive web that attaches to an object and can be used to lift a weight up to and over 80 times the weight of that device. The Silklab team verified this ability in a series of small-scale adventures, hoisting a steel bolt, pulling a test tube from water, and retrieving a scalpel partially buried in the sand. They were also able to use their “web shooter” to grab a wood block around 12 centimeters away.

The team has a long way to go before they can replicate the web-mastery that spiders have over their silk. The silk spiders can spin naturally, is more elastic than the fiber created by the team, and is also around 1,000 times stronger than their artificial thread.

The Silklab crew now aims to apply their innovation and imagination to improve their web-shooters and find applications for this new technology. The scientists’ real goal, though, is to replicate Spider-Man’s web-spinning ability.

“If you look at nature, you will find that spiders cannot shoot their web. They usually spin the silk out of their gland, physically contact a surface, and draw out the lines to construct their webs,” Lo Presti said. “We are demonstrating a way to shoot a fiber from a device, then adhere to and pick up an object from a distance. Rather than presenting this work as a bio-inspired material, it’s really a superhero-inspired material.”

Reference: Gianluca M. Farinola, Fiorenzo G. Omenetto, et al, Dynamic Adhesive Fibers for Remote Capturing of Objects, Advanced Functional Materials, (2024). DOI: 10.1002/adfm.202414219

Feature image credit: Marco Lo Presti, Tufts University