Image credit: Srinivas Sudagani Unsplash

Scientists have recently found a way to use sunflower pollen to develop a new ink for 3D printing that could be used to fabricate parts useful for tissue engineering, toxicity testing, and drug delivery.

“Utilizing pollen for 3D printing is a significant achievement as the process of making the pollen-based ink is sustainable and affordable,” said contributor Professor Cho Nam-Joon of the Nanyang Technological University, Singapore (NTU) School of Materials Sciences and Engineering. “Given that there are numerous types of pollen species with distinct sizes, shapes, and surface properties, pollen microgel suspensions could potentially be used to create a new class of eco-friendly 3D printing materials.”

Currently, the most widely used bioprinting method is a technique called extrusion-based bioprinting, in which inks are dispensed continuously from nozzles and deposited along digitally defined paths to fabricate 3D structures layer by layer. One of the challenges of this method is the difficulty in retaining the structures and shapes of soft and delicate materials, such as hydrogels, cells, and biopolymers, without additional support.

“Bioprinting can be challenging because the inks used is typically too soft, which means the structure of the envisioned product may collapse during printing,” added Nam-Joon. Often, a supporting matrix, into which the soft ink is deposited during the printing process, is typically used. However, this creates waste since the supporting matrix becomes unusable after printing.

But the new ink is able to hold its own shape when deposited onto a surface, making it an attractive and viable alternative, especially when it comes to applications in medicine. “Through tuning the mechanical properties of sunflower pollen, we developed a hybrid ink that can be used to print structures with good structural integrity,” said Nam-Joon.

Applications in biomedicine and tissue engineering

To make their pollen-based hybrid ink, the researchers incubate sunflower pollen in an alkaline (basic) solution — an environmentally-friendly process similar to soapmaking — for six hours to form pollen microgel particles. The pollen microgel is then mixed with hydrogels, such as a polymer called alginate, typically obtained from brown seaweed, or hyaluronic acid, a clear, gooey substance produced by the body.

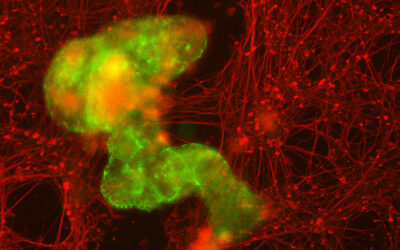

They then printed a five-layer tissue engineering scaffold — used to culturing cells — in just 12 minutes. Collagen was then added to the scaffold to provide anchor points that cells can adhere to and grow. The scientists then seeded human cells on the scaffold and found it to have a high cell-seeding efficiency of 96-97%. This is comparable performance to the inverted colloidal crystal (ICC) hydrogels that are widely utilized as 3D cell culture platforms but that are time-consuming and laborious to fabricate.

“Our findings could open new doors to customized flexible membranes that fit the human skin’s contours exactly, such as wound dressing patches or facial masks,” explained Professor Song Juha from the NTU School of Chemical and Biomedical Engineering. “Such soft and flexible membranes are usually manufactured based on flat geometry, thus resulting in problems such as fractures in the layers or a poor fit when applied on large surface areas of skin, such as the face or areas that see frequent movement like the joints.”

Recyclable support matrix

The scientists also found that that the soft and flexible pollen microgel particles could serve as a recyclable support matrix for use in freeform 3D printing. To test the feasibility of their approach, they fabricated a 3D-printed silicon rubber mesh for the elbow using pollen microgel as the support that would retain the elbow mesh’s shape as it is being printed.

After curing the printed product at 75°C (167°F) for 24 hours inside the pollen microgel, the printed 3D-silicone rubber mesh could adapt to the human elbow curvature. They also found that the mechanical properties of the silicone rubber samples printed and cured in the pollen supporting matrix were similar to those of samples fabricated via the traditional casting method.

Drug delivery

“There is also potential for the pollen-based scaffold to be used as a smart drug carrier, given pollen’s stimulus-responsive nature,” said Nam-Joon. “For instance, we can further slow down the release of drugs by coating the pollen-based scaffold with a thin layer of alginate, and stimulate the release by introducing an acid.”

Given that pollen responds to pH changes, the team also tested the viability of the 3D scaffold as a stimulus-responsive drug delivery system. When a fluorescent red dye was dripped onto the scaffold, the pollen microgel particles released the dye into the scaffold gradually. The amount and rate of release increased with the addition of an acid, demonstrating their use as a drug delivery system with controlled release.

“Pollen microgel particles have a hollow shell structure, which means they could potentially be used to carry drugs, cells, or biomolecules in drug delivery platforms with customised 3D structures,” said Nam-Joon. “We are now looking at how we can use these pollen microgel scaffolds for 3D cell culture platforms in various biomedical applications.”

The use of pollen in the biomedical field builds on the NTU research team’s body of work on repurposing pollen grains, a natural renewable resource, into a building block for various eco-friendly alternative materials, from eco-friendly paper to biodegradable sponges that can soak up oil pollutants.

The team is now looking to collaborate with industry to refine their 3D printing innovation and advance its commercial uptake.

Reference: Shengyang Chen, et al., Engineering Natural Pollen Grains as Multifunctional 3D Printing Materials, Advanced Functional Materials (2021). DOI: 10.1002/adfm.202106276