Current plastics technology is overwhelmingly reliant on feedstocks from fossil fuels, and, in many cases, are still non-biodegradable substances (although recycling is able to deal with an ever-increasing range of materials). With declining reserves of resources and the correlated rise in interest in sustainable materials, research towards viable alternatives for plastics in packaging, consumer products and even medical supplies is continuing apace.

Current plastics technology is overwhelmingly reliant on feedstocks from fossil fuels, and, in many cases, are still non-biodegradable substances (although recycling is able to deal with an ever-increasing range of materials). With declining reserves of resources and the correlated rise in interest in sustainable materials, research towards viable alternatives for plastics in packaging, consumer products and even medical supplies is continuing apace.

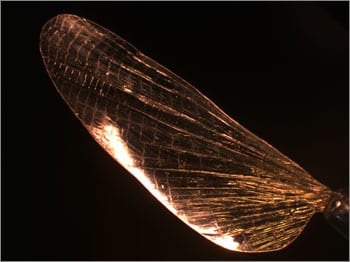

Materials scientists have once again turned to the lessons of nature in addressing this issue. Javier Fernandez and Donald Ingber of Harvard University took chitosan (commonly found in the shells and carapaces of mollusks and insects) and fibroin (silk), and deposited them sequentially to develop a layered composite material that they christened “shrilk”: a chimera of the shrimp and silkmoths that provided the raw materials. The dry material demonstrates strength and toughness similar to aluminum alloys. When water is added, strength is sacrificed but the elasticity improves.

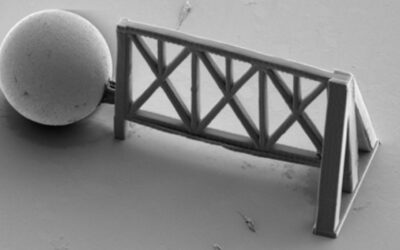

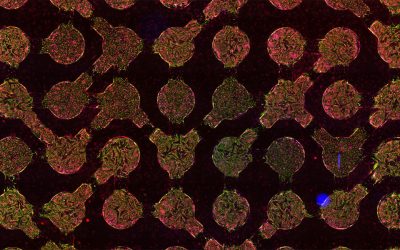

The films can be deposited on patterned molds to impart a specific patterning to the surface, and being able to tune or switch the elasticity allows simple engineering of 3D structures. The materials are biocompatible (and thus feasible for biomedical applications: the authors envision a tissue-engineering scaffold in the paper), biodegradable, and biosourced, presenting a truly sustainable and environmentally friendly wrapper for your next plastics purchase.