Human muscles possess many excellent and fascinating properties such as fast response, great flexibility, high strength and self-healing abilities. For many years, the challenge for engineers and researchers has been to find a technology that can match these properties. An emerging technology with potential – in the near future –to even outperform human muscles is the principle of dielectric elastomer transducers (DETs). DETs have many potential and diverse application areas such as artificial muscles, valves and pumps, wave energy generators, and ultra-thin loudspeakers. DETs consist of a thin elastomer membrane sandwiched between two ultrathin and flexible electrodes. When a voltage is applied to the DET it has the ability to change its size and shape and can also be used to generate energy when subjected to mechanical deformation. DETs can consequently be used as sensors, actuators, and generators.

Human muscles possess many excellent and fascinating properties such as fast response, great flexibility, high strength and self-healing abilities. For many years, the challenge for engineers and researchers has been to find a technology that can match these properties. An emerging technology with potential – in the near future –to even outperform human muscles is the principle of dielectric elastomer transducers (DETs). DETs have many potential and diverse application areas such as artificial muscles, valves and pumps, wave energy generators, and ultra-thin loudspeakers. DETs consist of a thin elastomer membrane sandwiched between two ultrathin and flexible electrodes. When a voltage is applied to the DET it has the ability to change its size and shape and can also be used to generate energy when subjected to mechanical deformation. DETs can consequently be used as sensors, actuators, and generators.

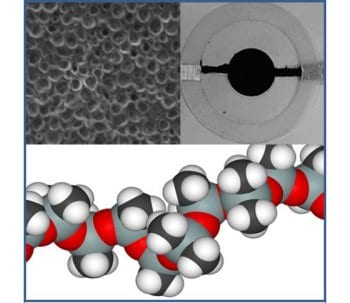

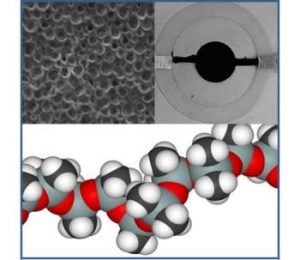

One of the most frequently used materials for the elastomer membranes in DETs are silicone elastomers, which are promising materials due to superior properties such as high efficiency, reliability and fast response times. Silicone elastomers furthermore have many interesting and desirable properties that many other materials do not possess, namely very high thermal stability, chemical and biological stability and inertness, ozone and UV resistance, hydrophobicity, transparency, high gas permeability, low glass transition temperature, and low surface tension. For the DET technology to progress towards industrial implementation, a leap in material development is required, specifically targeting longer lifetime and higher elastomer energy densities to provide more efficient transduction at lower driving voltages.

Anne Ladegaard Skov and co-workers (Technical University of Denmark) now present a timely and comprehensive review about the current state of silicone elastomers for DETs. This includes the different material strategies that have up to now been used to improve silicone elastomers for DETs. The pros and cons of different approaches such as using commercial elastomers, composites, polymer blends, grafted elastomers and complex network structures are discussed and evaluated and recommendations for next steps in material development are suggested. Furthermore material requirements and parameters for silicone DETs are given based on their chemical, physical and electrical properties. It was found that for the technology to be commercially viable in the future it is essential that all aspects of the elastomer are taken into account, namely dielectric losses, lifetime and the very often ignored polymer network integrity and stability.