What if you could monitor your heartbeat or detect the intensity of physical exercise by measuring your sweat using nothing but your t-shirt? While this might seem like sci-fi dreams for the future, these types of technologies are already becoming part of our daily lives. Wearable electronics and smart clothes hold great promise, with scientists around the world already testing new materials for conductive inks and flexible materials to design new kinds of electronic textiles.

By exploiting the thermoelectric effect—which involves the conversion of temperature differences into electric voltage—researchers can explore new materials for flexible thermoelectric nanogenerators suitable for wearable electronic applications. However, current commercially available thermoelectric devices are usually rigid and based on non-environmentally friendly and/or expensive inorganic components.

“Consequently, there is massive interest in fabricating flexible and wearable thermoelectric materials based on doped organic semiconductors,” the authors stated in the study.

This was the challenge facing Dr. Pietro Cataldi of Smart Materials at Istituto Italiano di Tecnologia who worked in collaboration with researchers from the Departamento de Biología Molecular y Bioquímica – Universidad de Málaga.

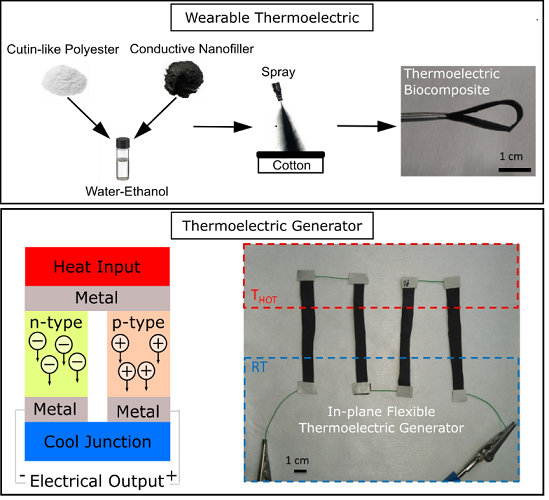

In their study published in Advanced Functional Materials, the team describes a new strategy to fabricate an environmentally-friendly fabric that generates its electricity from the temperature difference between the human body and its surroundings. In particular they report an easy, cost-effective, and scalable fabrication method for organic textile materials which employs fully biodegradable thermoelectric polymers. The design contains two types of semiconducting materials, classified as n- and p-type semiconductors, the combination of which has previously not been accomplished.

Cotton was chosen as the base fabric due to its natural origin, light weight, biodegradation, and large-scale availability. The cotton was sprayed with thermoelectric inks prepared by mixing carbon nanomaterials, such as graphene nanoplatelets, carbon nanotubes, and carbon nanofibers, with aleuritic acid in water-ethanol (see figure).

The resultant biocomposite displayed remarkable electrical conductivity. The biodegradability of these new thermoelectric materials was proven using oxygen demand tests, and the stability of the electrical properties to bending and washing was found to be dependent on the type of nanofiller used.

Due to the ease of fabrication, the green manufacturing, the flexibility and sustainability of the biocomposites, the presented thermoelectric materials lay the foundation for a future generation of wearable devices, safer for the environment and more easily disposable.