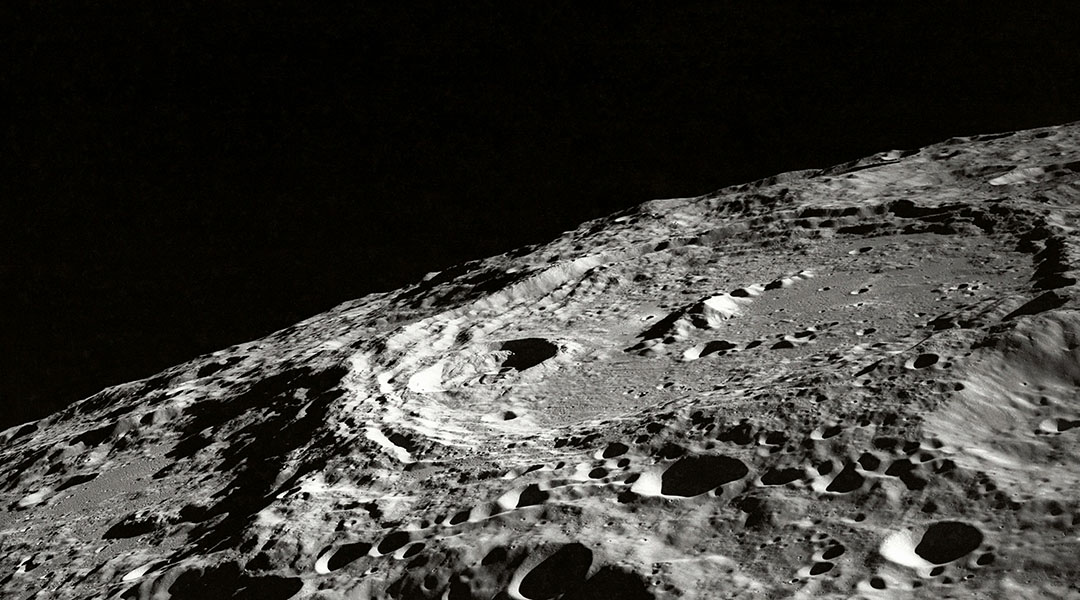

Scientists have found a way of making solar panels using moon dust. This could drastically slash the cost of transporting solar panels to space, by making them on the Moon instead.

One day, these solar panels could power a permanent base on the Moon.

While solar cells are essential for space exploration, lifting them into space is no easy feat. That’s why scientists around the world are looking at ways of making the load lighter.

“Every kilogram you launch into space is expensive,” said Felix Lang from the University of Potsdam, who led the development of the new solar panels. “If we can make solar panels on the Moon, we can cut that weight by 99%.”

To show this approach is feasible, Lang and colleagues melted a material similar to regolith — the rocky debris found on the Moon — to make glass, which they then used to build a working solar panel.

While the panels are not as efficient as the most sophisticated technology made on Earth, they offer a significant trade-off. The researchers estimate that for every gram of material sent to space, the Moon-made solar panels could produce up to 100 times more energy than traditional solar panels that have to be flown in.

Making moonglass

Initially, Lang’s research group was experimenting with using ultra thin glass to make lighter solar panels that would be easier to lift into space. However, this can make the glass difficult to handle and vulnerable to the harsh radiation on the Moon.

The idea of manufacturing the glass on the Moon sparked when Lang met with collaborators from Technische Universität Berlin, who were interested in making glass out of moon dust.

Roughly 50% of moon dust is made of silica particles — the main ingredient used for making glass — making it a great candidate to substitute Earth-made glass.

But while astronauts have brought back some lunar soil to Earth, getting hold of a sample is not easy. Instead, the scientists used Earth materials to replicate not just the composition, but also the shape and size of the particles that make up moon dust.

For instance, the lack of wind and water on the Moon means there’s little erosion, and dust particles are much sharper than those found on Earth.

It turns out that making moon glass is actually quite simple; it only requires melting the moon dust. On the Moon, this could be achieved with a solar furnace, which uses mirrors to concentrate sunlight, reaching temperatures high enough to make glass.

“We wanted to use the regolith without any purification steps, because that would mean [bringing] a lot more equipment on the moon,” said Lang.

To make working solar panels, the moonglass was paired with perovskite — a type of crystal material that is very efficient at turning sunlight into electricity. It’s also a very robust material that can make working solar cells even when there are defects.

“This is one big advantage of using perovskite compared to, for example, silicon, where defects can kill performance immediately,” said Lang.

The researchers estimate this process would allow them to make 400 square meters of solar panels by launching just 1kg of perovskite crystals to the Moon.

Powering space exploration

Lang said that the most surprising discovery was how well the moon glass could resist radiation. Without the protection of an atmosphere, the Moon is exposed to harsh radiation, which makes glass turn darker, reducing the efficiency of solar panels over time.

However, the moonglass was not affected. The scientists found this was thanks to iron impurities, which made up about 1% of the moonglass.

Solar panels made with the moonglass achieved up to 10% efficiency. While this is lower than the most efficient solar cells in use today, which can reach over 40% efficiency, the 99% savings on transport costs far outweigh this difference.

“We are still trying to crank the efficiency up,” said Lang. By tweaking the thickness of the glass and connecting solar panels in tandem, they have been able to reach over 23% efficiency with Earth-made glass. Next, they want to look into implementing these improvements in moonglass panels.

The team also plans to look into how changes in temperature will impact these panels over time, as temperatures on the Moon can range from -130°C to 120°C.

“We want these solar cells on the Moon to last long,” Lang emphasized.

Within the next five years, the researchers are hoping to launch a small-scale experiment to make and test these solar planets under the actual conditions of the Moon. Eventually, they are also considering the possibility of using a similar approach to make solar panels using dust from Mars.

Reference: Cuervo-Ortiz et al., Moon photovoltaics utilizing lunar regolith and halide perovskites, Device (2025). DOI: http://dx.doi.org/10.1016/j.device.2025.100747

Feature image credit: NASA