Organic–inorganic hybrid materials have gained a lot of attention in recent years owing to their light-emitting qualities. Specifically, so-called “perovskite” crystals of such materials have shown wide-ranging applications in chemical and radiation sensors, memory devices, light-harvesting devices, light-emitting diodes, and light-emitting transistors. These lattermost applications being technologically important for the very computer, phone, or tablet screen you are reading this from. Furthermore, these materials are low-cost, have high photoluminescence quantum yield (PLQY), and have color light emission that is easily-tunable.

These materials are taken a step further in research published in Small, where organic–inorganic perovskite materials are made into nanofibers, resulting in superb long-term stability and light-emitting properties.

One of the main characteristics of such perovskite crystals is that the smaller the crystal, the better the optical properties, and it is found that entrapment of these crystals in a nanofiber—in a process known as electrospinning—the size of the nanocrystals is easily regulated. The authors in this highlighted work demonstrate a “one-pot” process of electrospinning nanofibers using perovskite crystals as the core material, and polyacrylonitrile (PAN) as the shell material.

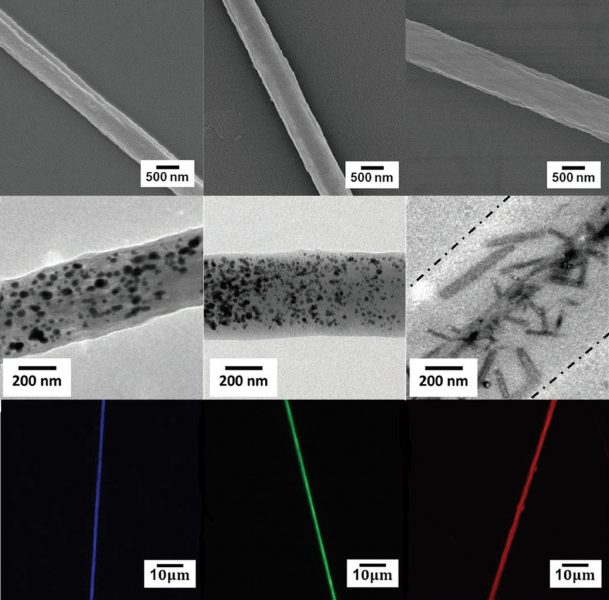

The perovskite crystals are varied in composition based on the halide group—being either chlorine, bromine, or iodine—as well as the ratio of the component organic-to-inorganic parts. These variations dictate the color of light emitted by the fibers upon exposure to ultraviolet radiation, as shown in the figure (right). For all three different fibers, the perovskite nanoparticles (black dots in the middle set of images) are clearly seen to be well inside the PAN shell and not on the surface.

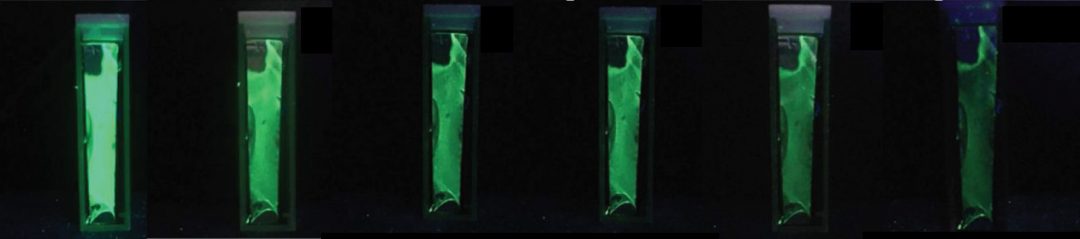

As PAN is waterproof, this has implications for the stability of the fibers in water. The picture below shows a vial of these fibers fully immersed in water, decreasing in luminosity over time. The picture on the far left is the same material after five days in water, and is still visible under UV light. Extraordinarily, the same perovskite-PAN material in the non-fibrous, thin-film form, completely degrades and loses all luminosity after just ten minutes in water.

This beautifully demonstrates the water-proofing capability of the PAN shell when these materials are made into nanofibers. Another experiment of the fibers at 28 °C in an environment of 80% humidity, showed that the nanofibers barely decreased in luminosity after 30 days, whereas the thin-film counterpart significantly degraded in the same environment after just 40 hours.

Furthermore, as a final experiment, a white-light emitting nanofiber was fabricated by mixing the ingredients for orange-light and blue-light emitting nanofibers in the electrospinning process.

This exciting research shows that simply changing the nano-scale structure of light-emitting perovskite-organic hybrid materials can drastically improve their optical performance as well as their long-term stability, even when exposed to moisture. And the colour with which they emit is easily tunable owing to the simple fabrication process. This material has very promising implications for technologies that depend on light-emitting diodes and transistors, and with the simple and cost-effective manufacturing process, could be of keen interest to the technology industry.

This manuscript was featured as the back cover of Issue 22, 2018 of Small: