Flexible physical sensing platforms (PSPs) that can detect and communicate with surrounding environmental data (e.g., physical information such as mechanics like force or strain, and temperature) are of interest in a variety of high-tech fields, such as for wearable electronics, soft robotics, and real-time healthcare monitoring.

With increasing demand for these applications, there is a corresponding increase in the requirements for the development and effective implementation of such sensors. Synthetic polymers, such as polycarbonate, polyethylene terephthalate, polydimethylsiloxane and silicone rubbers are usually used as the PSP substrates due to their optical transparency and excellent flexibility.

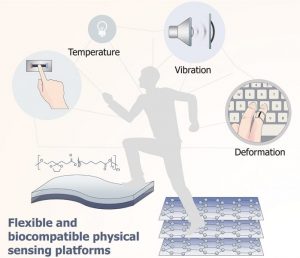

Flexible and biocompatible physical sensing platforms.

In particular, polydimethylsiloxane and silicone rubbers are two of the most widely used materials owing to their additional advantages of compliance and stretchability. However, a crucial question remains relative to the design and assembly of PSPs that can meet the multitude of additional requirements for many of these devices, such as biocompatibility and high-sensitivity to the target factor.

In this study, group of Prof. David L. Kaplan designed a flexible, physical sensing platform based on graphene ink and the de novo synthesis of a biodegradable copolyester. Unlike other PSPs whose responsiveness is related to functional components or specifically designed structures, the sensitivity of these new PSPs is derived from the reaction of a smart substrate layer due to specifically designed chemical configuration and moderate structural transition temperature (around 37 °C).

This PSP provided an active substrate to sense mechanical and temperature stimuli, such as body temperature, the temperature of a light bulb, vibrations from sound, the touch of a finger, and movement. These responses demonstrate promising applications in healthcare, human-machine interfaces, and soft robotics.

Read more about these findings in the article that has recently been published in Advanced Materials Technologies.