Wearable electronics are gaining momentum in recent years. The term refers to smart electronic devices that can be worn on or implanted, and whose applications include physiological monitors or biomedical sensors, energy conversions and storage, wireless communication and charging systems, as well as human-machine interfaces. They are required to be conformable in order to enable good signal quality during the movement of the wearer, as well as lightweight and long-lasting.

Incorporating electrically functional fibers into textiles is a convenient method to impart sensing and readout functionality in the form of wearable clothing. However, a weak point for the development of versatile wearable electronics is that they must be water resistant: people may sweat or get caught in the rain. It would be a pity if these devices stopped working due to moisture. In the extreme case where devices are used under water, the device not only needs to be waterproof, but also pressure resistant.

With such wearable electronics, underwater activities can be effectively detected or analyzed, such as monitoring electrophysiological signals for athletes when they are training in the rain or water. And they can be used for detecting the movement, migration, and health of animals living in oceans or lakes.

Therefore, designing stretchable, conductive fibers capable of working in submerged environments is fundamentally essential to the evolution of this technology. Though conductive fibers with waterproof or splash-resistance have been studied, stretchable conductive fibers that are capable of maintaining good conductivity at high strain, as well as full water resistance, have not been reported yet.

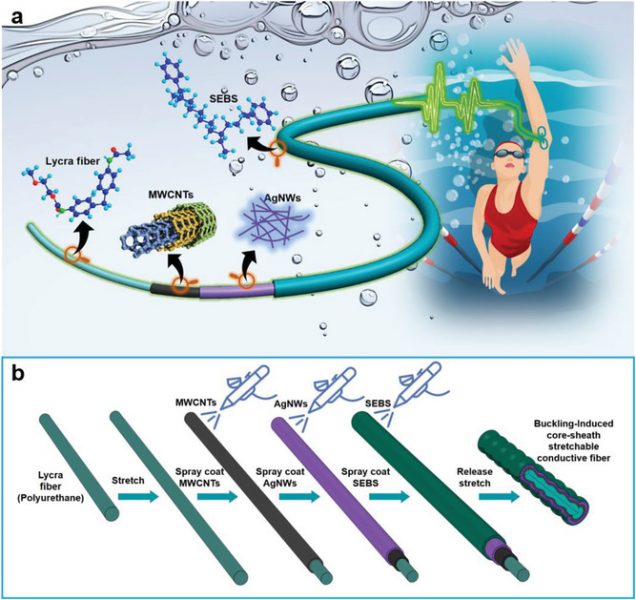

To address this, Professor Nan Liu and her colleagues from Beijing Normal University, China, have developed a core-sheath stretchable conductive fibers for underwater wearable electronics. Their research is published in Advanced Materials Technologies and enables practical applications of stretchable conductive fibers in underwater environments. The polyurethane fibers are made with layers of carbon nanotubes, silver nanowires and a soft-biofriendly-rubber-like polymer. Pre-straining induced wavy structure was used to enhance stretchability of conductive materials.

“This work gives us a reference to systematically develop underwater wearable electronics with safety and durability, especially underwater electronic textiles,” says Yan Zhang, the study’s first author.