Fabrics able to act as electronic textiles can convey signals to and from the human body—as sensors for health and fitness monitoring, for example—without looking or feeling very different to the clothes we wear now.

The integration of multiple devices over a large, complex area means having to carefully position the components and then reliably connect them. The inclusion of conductive threads within the fabrics requires no new manufacturing technology and has proven effectiveness as wiring but, for greater flexibility and with the maximum comfort of the wearer in mind, a more advantageous strategy may be to print circuitry onto the fabric’s surface using specially formulated inks instead.

The moment that a fabric is stretched, however, any pattern printed on it cracks and separates. This is no big deal for purely decorative pictures and text, but a printed circuit would be compromised and eventually irreparably damaged by the repeated flexing of the fabric beneath it. So far, inks designed to be stretchable have shown undesirable changes to their electrical resistance as they flex, making the circuit conductivity and therefore the ability to use any connected devices unpredictable.

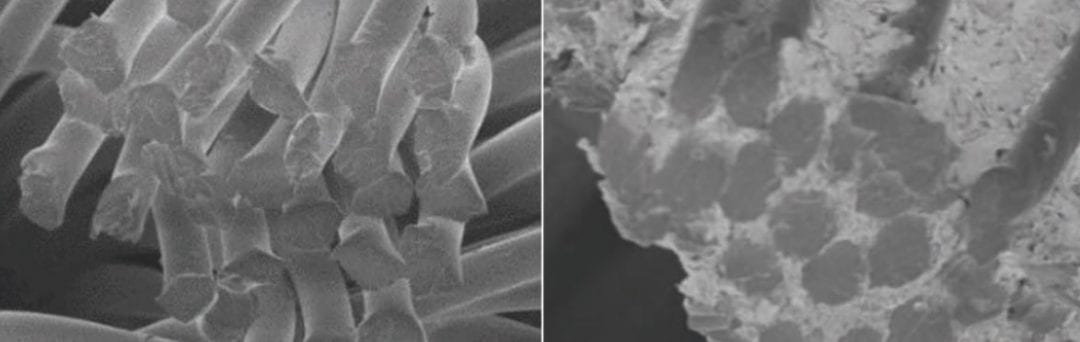

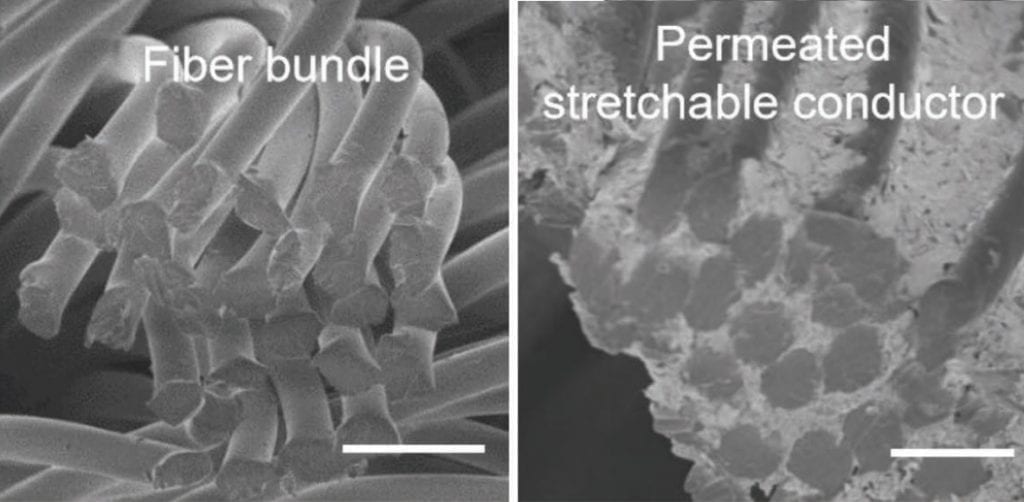

A group of researchers working in Tokyo, Japan, have now formulated a conductive ink which partially incorporates itself into the fabric. When the fibre bundles flex and separate, the ink between them keeps the pattern connected, maintaining the integrity of the printed circuit without gluing the fibres together and preventing normal motion.

The ink is composed of a chemically stable fluoroelastomer with the required mechanical properties, 2-3 µm flakes of silver as a conductive filler, and butyl carbitol acetate to aid the permeation of the ink into the fabric through a controlled evaporation. The researchers say that this perm eability of their ink is the key to its demonstrated stretchability of up to 450% on normal textiles with a low sheet resistance of only 0.06 Ohms per square, comparing favourably with the current state of the art.

The ink is composed of a chemically stable fluoroelastomer with the required mechanical properties, 2-3 µm flakes of silver as a conductive filler, and butyl carbitol acetate to aid the permeation of the ink into the fabric through a controlled evaporation. The researchers say that this perm eability of their ink is the key to its demonstrated stretchability of up to 450% on normal textiles with a low sheet resistance of only 0.06 Ohms per square, comparing favourably with the current state of the art.

A circuit based on this ink was printed onto a skin-tight compression band to create an electromyogram system, able to monitor muscle contractions in a volunteer’s arm as the fist was opened and closed. The readout, including the noise level, was compared to that of a conventional electrode. See the results of this application test in Advanced Materials.