Strong permanent magnets made with rare-earth metals are at the heart of modern technology, but their limited supplies and high cost limit their applications. Nanotechnology now enables the generation of strong magnets with smaller amounts of rare-earth metals.

From mobile phones to high-efficiency washing machines, from electric cars to wind power generators, permanent-magnet materials have become ubiquitous, and their impact on our lives and society is growing at an accelerating rate for energy generation and high-efficiency utilization. However, existing strong magnets based on rare-earth compounds are extremely expensive and suffer from the limited supplied of the rare-earth metal component. In an article published recently in Advanced Materials, Prof. Xiangyi Zhang and his team from the State Key Laboratory of Metastable Materials Science and Technology (Yanshan University, China), demonstrate a nanostructuring strategy that can fabricate strong magnets with a smaller amount of rare-earth metals. Their synthesis method enables the resulting nanostructures to show impressive record-high performance.

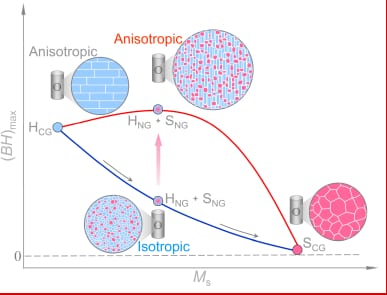

Synergy between hard and soft phases at the nanoscale. More information here.

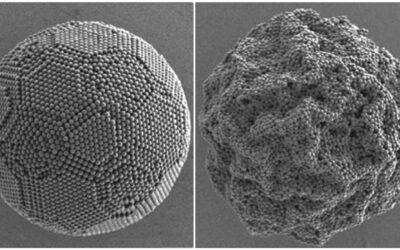

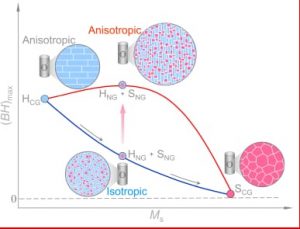

The performance of a permanent-magnet material is usually evaluated by the figure of merit – the energy product (BH)max. Obtaining a large energy product requires high magnetization (Ms) and high coercivity (the reverse-field strength needed to reduce the magnetization to zero); however, these properties do not go hand in hand. For example, soft-magnetic (S) materials have high magnetization but low coercivity, while hard-magnetic (H) materials have large coercivity, but small magnetization. The conflicting properties limit the development of strong magnets. Two decades ago, a novel idea emerged that brought hope to strong magnets. Scientists proposed that an exchange-coupled nanocomposite magnet that combines a rare-earth hard-magnetic material with a soft-magnetic material has the potential to be stronger and less expensive than pure rare-earth magnets. However, such a strong bulk composite magnet has been elusive due to technical challenges in generating the theoretically required nanostructures: aligned hard-phase grains and homogeneously distributed soft-phase grains with high fractions (>20%) and small sizes (≈10 nm). Simultaneously achieving all of these characteristics in a bulk material has been considered as an engineering nightmare by scientists in the field.

Prof. Zhang and his team have devised a novel strategy to generate anisotropic bulk nanocomposites with the desired structures. The resulting nanostructure exhibits a record energy product for bulk nanocomposite magnets with a smaller amount of rare-earth metals and outperforms, for the first time, corresponding pure rare-earth magnets (with 58% enhancement in energy product). This unprecedented performance is achieved by using a strategic multistep deformation approach that enables separate control over the properties of the soft and hard phases, thus yielding the desired nanostructures.

The findings provide an exciting new strategy and direction in the quest for stronger permanent-magnet materials with fewer critical elements. Moreover, similar nanostructuring behaviors have been observed in other magnetic material systems; thus, these findings are generally significant and may find tremendous potential for technological applications in other advanced materials, where precise control of nanostructuring is crucial for determining their functional properties.

Kindly contributed by the Authors.