The groups of Tour and Ruiz-Hitzky have both used a simple process to produce high quality graphene starting using a range of interesting, and even surprising, feed-stocks, including common household spices.

Nanotechnology has taken the material science world by storm. Drop the words graphene, carbon nanotubes and such, and you’re bound to grab the attention of some editor/grant assessor/supervisor. Using these types of functional nanofillers to achieve high-end applications is often where the focus is placed. But now two groups independently and simultaneously show just how interesting the production of these fillers can also be.

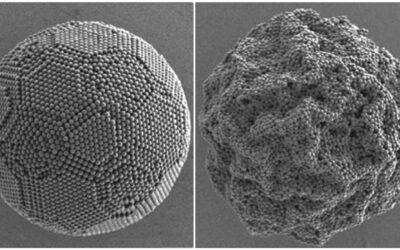

To make a carbon-based filler you need a carbon-based feed-stock. Conventionally, researchers have used carbon-containing gases (CO2, methane, thiophene, etc); most likely the purity of these stocks is high that it minimizes catalyst contamination. But what about following the old fashioned method of turning hydrocarbons to pure carbon sources? Nature has done it for many years; add some heat, take away oxygen, and out comes carbon (after some time, of course). The groups of Tour and Ruiz-Hitzky follow this simple process to produce high quality graphene starting using a range of interesting, and even surprising, feed-stocks.

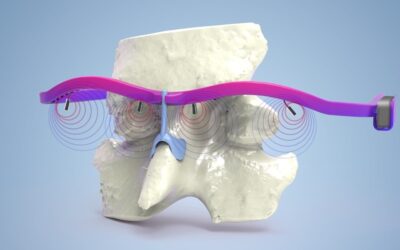

Ruiz-Hitzky et. al. demonstrate a clay-supported methodology using sucrose and gelatine as feed-stocks. A graphene composite monolith with a high conductivity is prepared. This is interesting considering that there is only 31% carbon in the final structure. These conductive composite monoliths could directly be used as electrodes in batteries, and more interestingly, bioelectrodes in biological sensors.

On the other hand, Tour et. al. produce pure graphene monolayers on copper-foils. These single layers are manipulated with polymeric films. They expanded their range of feed-stocks from sugary cookies and chocolate all the way to cockroach legs and dog faeces.

Just goes to show how true the saying “one man’s trash is another man’s treasure” really is.