Liquid polysiloxane materials set new record for high stretchability and challenge classic theory of elastomeric behavior.

Although you may think “elastomeric” and “liquid” are two words that would never go together, it is happening now. In an effort to develop a one-pot multigenerational synthesis for dendrimeric polymers, Jonathan Goff, Barry Arkles, and colleagues at Gelest Inc. and Lawrence Livermore National Laboratory (both in the United States) have discovered a completely novel class of liquid materials based on polysiloxanes behaving as elastomers, capable of shape recovery from extreme distortions that no other materials can handle.

Although you may think “elastomeric” and “liquid” are two words that would never go together, it is happening now. In an effort to develop a one-pot multigenerational synthesis for dendrimeric polymers, Jonathan Goff, Barry Arkles, and colleagues at Gelest Inc. and Lawrence Livermore National Laboratory (both in the United States) have discovered a completely novel class of liquid materials based on polysiloxanes behaving as elastomers, capable of shape recovery from extreme distortions that no other materials can handle.

The team has focused on making heterobifunctional siloxane macromonomers with precise compositional control. In order to obtain such macromers in high purity, they use a living anionic ring opening polymerization method to prepare poly(dimethylsiloxane) terminated by monovinyl and monohydride groups, where the number of repeating units well correlates to the equivalence of hexamethylcyclotrisiloxane. These products can then undergo platinum-catalyzed step-growth hydrosilylation polymerization, with a scale up to the multi-kilogram level.

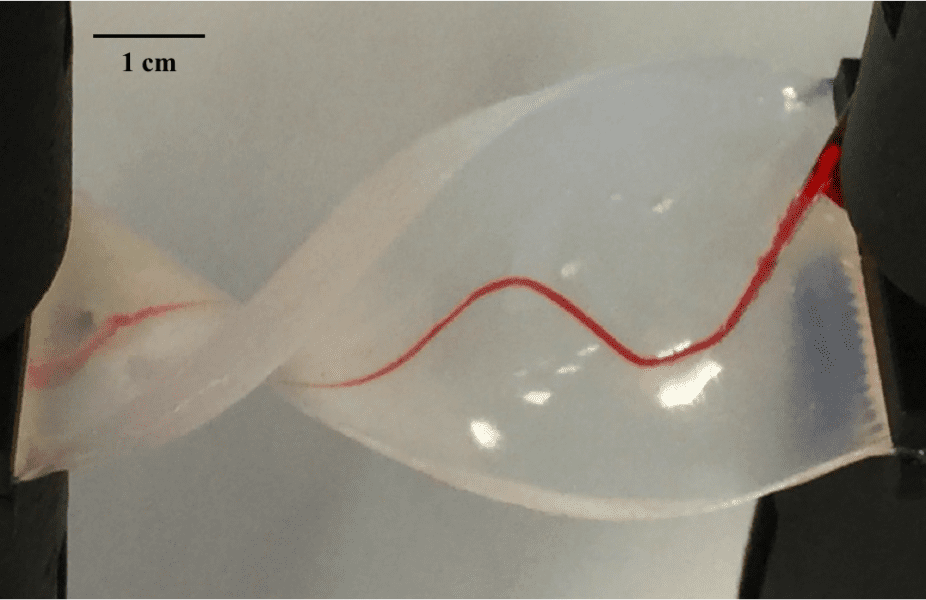

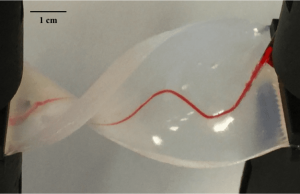

The polysiloxanes are found to be highly stretchable, with 800–2500% elongations depending on the molecular weight of the macromonomers. When reinforced with silica nanoparticles, the composites can reach tensile strengths and elastic elongations as high as 11 MPa and over 5000%, respectively. This is a revolutionary improvement in the realm of elastomers. For example, a regular rubber band breaks at around 200–300% elongation, and a high-performance stretchable elastomer at 1000%. However, it is rather surprising that there is no evidence indicating crosslinking in the linearly polymerized siloxanes, and they are characterized only as simple non-Newtonian liquids. This behavior is so perplexing that it can not be accounted for by the classical mechanisms accepted for elastomeric behavior.

With this surprising and remarkable discovery, the team plans to further increase the elongation of the material, and at the same time perform computational studies to help explain the mechanism of elastic recovery, according to Dr. Goff and Dr. Arkles. In addition to the excellent elastomeric properties, these polysiloxane materials are readily manufacturable and economically practical, and therefore, Dr. Goff and Dr. Arkles also hope to expand this work on high-elongation materials to other polymer systems in the context of stretchable electronic and medical-device integration.