Have you ever sprained your ankle or wrist? Or worse, broken them? Perhaps you once twisted a joint to a position it’s not supposed to be in. Perhaps when you’re recovering from such mishaps, the splint or support for your joint restricts your movement to an inconvenient degree.

The shortcomings of these supports comes primarily from the fact that the mechanics of tissue movement, such as joints and muscles, are complex and nonlinear.

Whatever your woes with joint injuries, additive manufacturing (AM)—perhaps more commonly known as 3D printing—may just be the solution for developing tailorable, programmable, and flexible support devices. Supports that can mimic tissue-like mechanics could provide better comfort for patients.

Two different 3D-printed meshes conforming to a knee, and sewn onto a glove.

With such applications of AM in mind, an international study led by researchers at MIT and Cambridge University, along with collaborators from South Korea and Mexico, developed biomechanically-tailored meshes for compliant wearable and implantable devices.

With an explicitly programmed toolpath (the path a machine tool follows to cut, etch, or print, etc.), the group could produce a bespoke mesh using AM to conform to a desired 3D structure on a patient. For example, a knee or hand, as shown in the figure.

In the case of the glove, the mesh provided extension forces when the fist was clenched, the idea being to reduce stiffening often seen in patients with certain brain injuries.

Furthermore, specific reinforcement along specific lines or sites on the mesh could be achieved, which gives the mesh specific flexible properties, such as being able to bend in one direction, but not in another.

This property was demonstrated on an ankle brace, where the specific mesh pattern allowed for the ankle to move freely and naturally, and at the same time preventing excessive inversion.

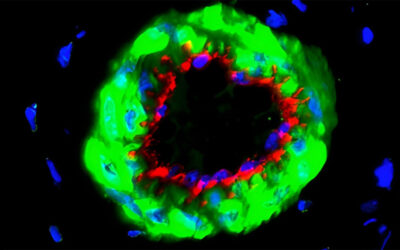

The authors are hopeful that if applied widely, such meshes with custom designs can be used for an array of medical applications, including comfortable implants that conform to internal tissue; an application perfect for hernia meshes.