Templating is the process of imparting artificial structures into a starting material. The technique has been demonstrated for many types of materials, which form structures that are either an inversion or a replica of the template.

In recent decades, self-assembling materials have been subjected to templating strategies, leading to the formation of new structures not present in either the template or the native self-assembling material. This shows the approach’s enormous potential for fabricating optical metamaterials — artificially structured materials with engineered electromagnetic properties. However, this requires the materials to be arranged in a sub-micron size range in order to interact with visible and near-infrared light.

A special class of composite materials called eutectics are available in a broad range of compositions and can form structures with characteristic lengths in the sub-micron regime. Eutectic materials are composed of elements or compounds that have different melting temperatures, which, when combined, form a mixture with a single, lower melting and freezing temperatures.

As the eutectic solidifies, its components self-assemble into 3D-structured composites, which have been regularly used in technological applications, including turbine blades and solder alloys. However, as these composites solidify from the melt, the self-assembled structures can form defects.

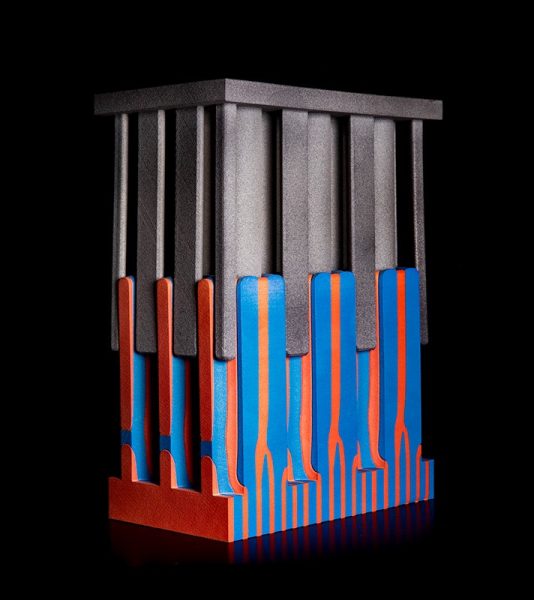

To address this obstacle, a team of researchers from the University of Illinois and University of Michigan proposed that the templating strategy could be used with eutectic materials to form new and complex mesostructures for optical applications. The science underpinning the concept of using templates to guide the organization of these composites and potential challenges were first reviewed in detail here.

“Materials are complex, but if you understand the underlying physics, you can build a model that can predict how they behave. The phase-field model allows us to simulate how a liquid solidifies to form various structures even when it happens within a complex template,” said Katsuyo Thornton, a professor at the University of Michigan who led the theoretical portion of the study; her graduate student Erik Hanson conducted the simulations.

Their team recently demonstrated a means of reconfiguring the simple layer-by-layer structure of the eutectic into tessellating patterns using their concept of templating. “We have previously shown the formation of new microstructures by templating a model system, namely silver chloride-potassium chloride eutectic, which naturally forms a layered pattern.

“When forced to freeze within a template, the kinetics of the solidification in these composites are modified such that the eutectic follows the constraints set by the template. So, by choosing an appropriate template like the one we show in this work, one could achieve tailor-made microstructures in these composites,” said Ashish Kulkarni, an Illinois graduate student and the first author of the study.

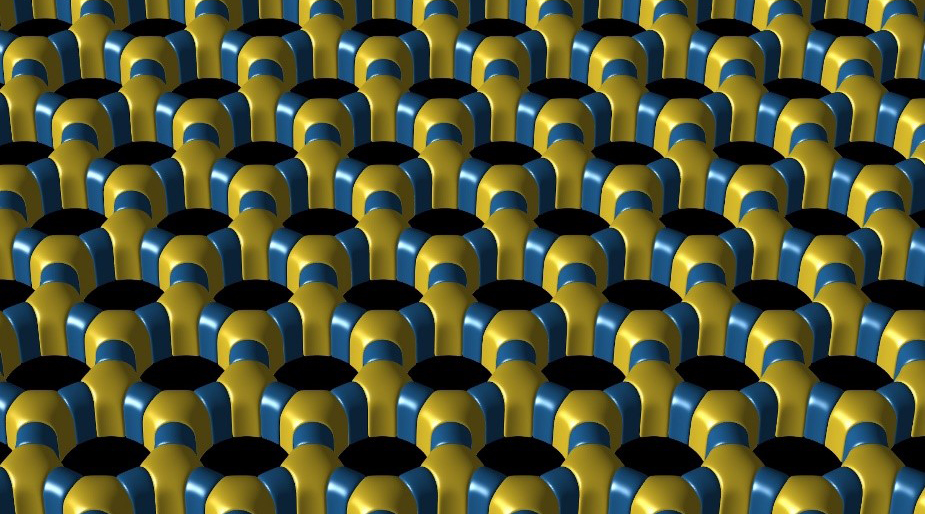

The researchers demonstrated that when a simple layered composite solidifies within a pillar template, it leads to the emergence of never-before-seen, spoke-like patterns. “Since the emergence of these patterns is determined by how fast the liquid solidifies, we have a simple knob in the form of rate of freezing that could be tuned to create different patterns,” said Paul Braun, professor at the University of Illinois and the lead author of the study.

In this work, they showed that the emergent microstructures bear a remarkable resemblance to Archimedean tessellations, which have been known since the 1600s, but are for the first time formed by templating inorganic materials.

“The implications of this work are far-reaching as this method could be used to make symmetry-breaking patterns in metal-dielectric composites and find use in non-reciprocal metasurfaces,” sais Runyu Zhang, a former Illinois graduate student and a co-author in this study. “This can be achieved by using different templates, which can be fabricated via holographic lithography as demonstrated in this paper.”

“Given the ability to selectively etch one the phases of the eutectic composite and the possibility of replacing it with a different material, this method could facilitate targeted microstructures for use as optical metamaterials,” concluded Kulkarni.

Kindly contributed by the authors